Reddonatura – A waste management system that gives back to nature and might be the answer to landfills

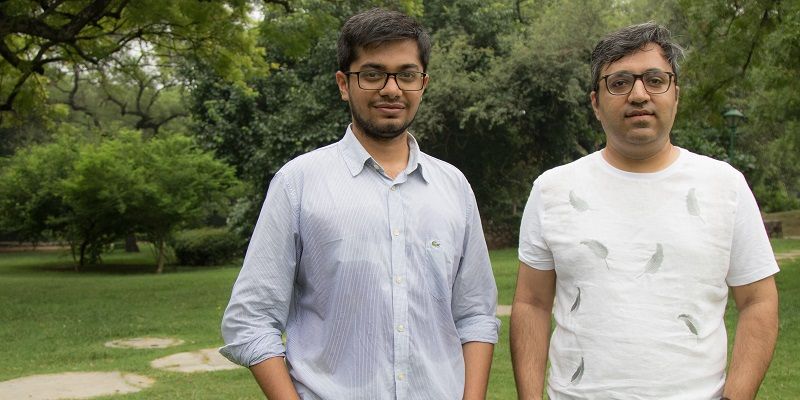

“You can never cross the ocean until you have the courage to lose sight of the shore.” Abhishek Gupta quotes Christopher Columbus in response to why he left a well-established family business to start a venture with his brother, Aayush Gupta.

With environment being a cause close to his heart, Abhishek decided to startup in the space. He adds, “Stumbling on the idea of waste management immediately struck a chord wherein both my passion towards the environment and the aspiration of venturing into something new were addressed. Waste management has always been a much unorganised sector and with our identified technology, I knew that we could create a change in this segment by offering a decentralised process which is the need of the hour.”Aayush started his career with the family business of gensets. When Abhishek expressed his desire to get into a new business, Aayush decided to take up the challenge with him.

Abhishek and Aayush founded Reddonatura three years back. ‘RNature’ by Reddonatura is a waste management system that decomposes kitchen waste into organic manure. The machine does not use any chemicals to do so, claim Abhishek and Aayush. Aayush adds, “The core solution that we sell is not only a business idea but will contribute to the well-being of people around as well.” ‘Reddo’ in latin means giving back and ‘natura’ means nature. The name fit with the ideology of the company and hence came to be.

Syed who is a chief engineer for Taj Vivanta, Yeshwantpur (Bangalore) told us that they use the 250 kg RNature since 2 years for waste management. He says, “The compost is used in the lawns. We initially bought the product because other than everything else, the price was the lowest, but we have continued to use it because of the efficiency and the responsiveness of the Reddonatura team. Suresh, who is the facility administrator for DELL, Whitefield (Bangalore), is a relatively newer customer who expressed similar sentiments. Syed and Suresh, both said that there is no foul smell from the machine as they keep the machine in a well-ventilated space.

How did the brothers see an opportunity in the space?

Abhishek and Aayush take Bangalore’s example and tell us how all of us have witnessed that infrastructure has not caught up with the demand, especially for waste management. Abhishek says, “We knew that urban areas were growing at a rapid pace and were falling short of solutions that could process the waste at a similar pace. The increased awareness on better waste management techniques paved the way for our products fitting into this segment. With the rise of various environmental concerns pertaining to the unscientific disposal of waste at the landfills, which was severely affecting the health of the people around these landfills, I was convinced that there would be a great potential for decentralised products.“

When Abhishek and Aayush were starting up, positive signs also came from the fact that awareness was spreading in all spheres – government was coming out with stricter waste disposal policies, residential societies were cracking down on garbage collection and disposal and there was a general wave of change everywhere. Abhishek chips in, “This was the same time that many Municipal Corporation across cities in India made it mandatory to install organic waste converters for any bulk waste generators. We found that making an in-vessel curing and composting method would save a lot of space as well, which would also be a great feature.” Aayush says, “The waste instead of being dumped into open grounds needed measures for treatment at source, which is where we identified into this space.”

Abhishek was awed by the Korea’s waste management system. During a trip he had an opportunity of visiting the waste management techniques adopted by the Koreans and its here that he came across decentralised machines, being used in every residential buildings, hotels and commercial establishments.

RNature

Abhishek got back to India and associated with the Korean company. The Korean company got a machine down to India, but unfortunately the system didn’t quite work as effectively as what they had seen in Korea. The duo tell us, “We came to understand that the process varies as the nature of waste generated in the other countries and in India is vastly different. What was needed is a system that could handle the kind of waste generated as per Indian conditions. That’s when we understood the need to develop a product as per Indian requirements. After 2 long years and with a lot of reengineering and changes to the system, we were finally able to come out with a product that was suited to our requirements.”

All you need to do is segregate waste and add the wet waste to the machine. The waste is then composted with the help of microorganisms that convert organic waste into compost. RNature uses ‘Thermophile Extremophile’ bacteria that is known to thrive in high temperature and are effective in high acidic or salty conditions. After 24–36 hours, the compost is ready. It looks like dry soil and is an excellent medium for growing plants. The compost produced is usually only about 10% of the quantity of waste the machine began with. The machine does need an electric and water supply, and should be kept in a place that has good ventilation. If a client is not able to use up the compost, the Reddonatura team buys it back from the client and sells it at organic/farmer’s market. Aayush says that sometimes corporates buy these manure bags and give it to farmers at heavily subsidised rates as a part of their CSR activities. RNature starts at 25kg capacity and goes up to 10 tonnes.

Abhishek adds, “We at the moment are the only company that can cater requirements right from 25 kg up to 10 tons catering B2B segment.” With proven outcome, shouldn’t they be entering the B2C market? Abhishek says, “Very soon we will also be launching our B2C segment of small composting machines that will cater to domestic, small and medium users ranging from 2 kgs to 5 kgs.”

Revenue model, target audience, and beating competition

Abhishek says that the target audience is anybody who are bulk waste generators – office campuses, IT parks, hospitality chains, hotels, hospitals, residential buildings, municipalities, malls, etc. Reddonatura is bootstrapped and the profits are pumped back into the business for scaling the operations. He adds, “We are also looking for funding to scale up our production capacity even more in the times to come. “

On beating competition, Abhishek says that product innovation is the key to success and they constantly tweak their technology to stay ahead of their competitor. Aayush adds, “Our products require much less time and space for waste processing and easy to install. And we continue to improve the quality of service and products to stay ahead of the competition.”

The duo is gung ho about ‘Make in India’ and want to take it to the world. Abhishek says that Reddonatura is in talks with other countries and is venturing into other renewable products and services apart from waste management products that will be manufactured in India.

On a parting note, Abhishek belts out the numbers that call for immediate attention, “Bangalore produces almost about 5000 tons of garbage every day. About 40% is the wet waste. Although we see a value in dry waste and an available market for it by recycling, it’s largely the wet waste that’s left out untreated and damages the environment.” Aayush gives some advice, which we can all benefit from, “Achieving a clean India is a combination of strong anti-litter policies, laws that are enforced diligently, responsible citizenship, sincere civic bodies and better working conditions for people who work on the streets, cleaning them. We the citizens also have a role to play, and most problems can be eliminated if we start segregating waste at the source daily, let the kitchen waste go into one bin and the recyclables go into another.