This 15-year-old is helping betel nut farmers save more through her automatic agri sprayer

After three years of conducting research, experimenting, and interacting with many betel nut farmers, Class 10 student Neha Bhatt developed an automatic agri sprayer capable of reducing human intervention, helping farmers save money.

Areca nut — more commonly known as betel nut or supari — has a great deal of commercial value attached to it. Belonging to the family Arecaceae, the tropical nut is used by a large section of Indians either for direct consumption or during certain religious practices.

Thousands of farmers in Kerala, Assam, and Karnataka have been immersed in cultivating the hardened woody fruit for years now. However, the occupation has not been a smooth sail for many.

Women farmers slicing the harvested betel nuts.

Image credit: Arjun Rajbanshi

Fahim Hussain, who leads the agronomy division at the Indore-based agritech startup Gramophone, sheds some light on this.

He says, “From non-availability of fungicides, lack of labour resources, to difficulty in containing pests, the supari farmers in India are struggling to get a good yield year-on-year. Insects like mites, spindle bugs, and tender nut drop generally destroy the plants and lead to diseases like Koleroga. Hence, there is a growing need for better technological interventions to assist the farmers.”

Fahim Hussain, an agronomist working with Gramophone.

Fifteen-year-old Neha Bhatt from Puttur in the Dakshina Kannada district of Karnataka witnessed one such issue that the farmers were facing in the region. But, unlike many of her age, Neha took it upon herself to find a solution for these ailing farmers.

Since 2017, every monsoon, Neha used to observe areca nut farmers spraying a fungicide called ‘Bordo mixture,’ composed of copper sulphate, lime, and water.

“The Bordo mixture was being applied specifically to protect the crops from fungus and mire. However, the farmers were diffusing the concoction using traditional steel fabricated gator pumps, which requires a lot of manual pressure. I found out that the entire process not only involved heavy labour cost but was also proving to be inefficient,” Neha tells SocialStory.

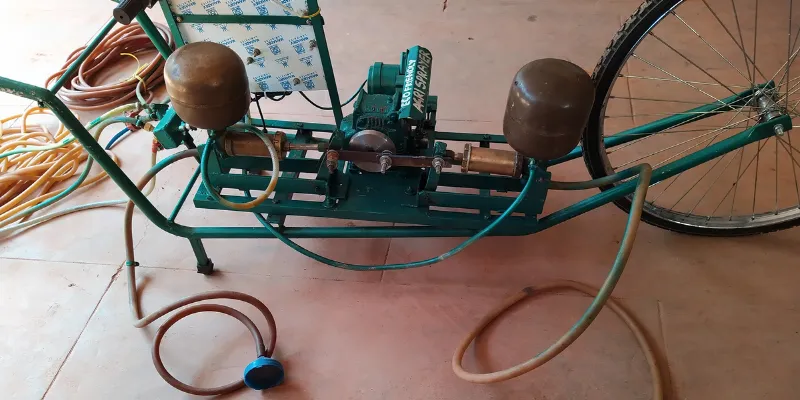

After three years of conducting research, experimenting, and interacting with many farmers, Neha developed an automatic agri-sprayer for them. The machine consists of an Arduino-based level detector, pressure release valve, and overcharge protector, and is capable of reducing human intervention, as well as saves time, and money.

Fifteen-year-old Neha Bhatt.

A Class 10 student of Vivekananda English Medium School, Neha bagged the third prize for her invention in the “CSIR Innovation Award for School Children, 2020”. She received a cash prize of Rs 30,000 and a certificate from the Council of Scientific and Industrial Research.

An impactful invention

It all began three years back when a 12-year-old Neha first witnessed the strenuous effort put in by the areca nut farmers. For the next two years, she constantly juggled between academics and a whole lot of research and groundwork to build a better system for them.

In June 2019, she got an opportunity to participate in Royal Dutch Shell’s global education programme NXplorers. The initiative focusses on equipping young boys and girls between the age of 14 and 19 to solve societal issues with the help of practical knowledge.

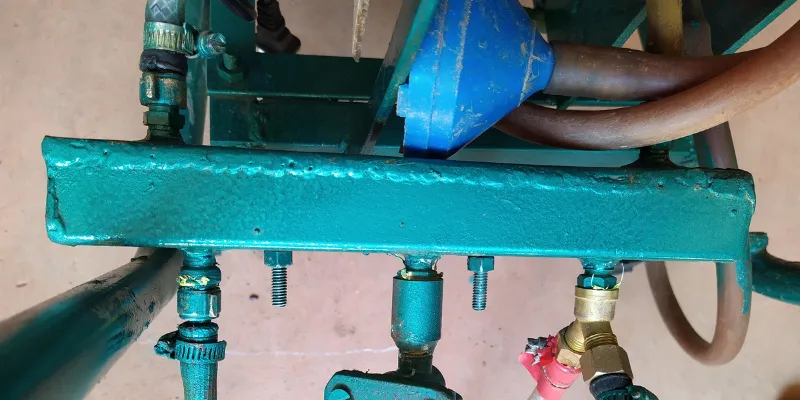

A part of Neha's automatic agri sprayer.

“The NXplorers programme was a turning point. It was a three-day workshop for which I registered at my school. It taught me how to apply science, technology, engineering, and mathematics (STEM) in my daily life, and specifically for problem-solving. That was when I thought of using my learnings to build an automatic sprayer for supari farmers,” Neha explains.

Neha attending the NXplorers programme.

She started by speaking to the local betel nut farmers and distributed questionnaires drafted in their local languages to understand their pain points better. She also spoke to multiple agronomists and experts to validate her ideas.

“Through my interactions and surveys, I got to know that more than 97 percent of the farmers were finding it hard to pay the high labour cost involved in using gator pumps. Besides, the physical exhaustion that was involved in mixing the pesticide, moving the lever to produce pressure, and finally, spraying it was draining them out, she notes.

An aerial view of the agri-sprayer.

After six months of trial studies at her school lab with various second-hand mechanical and electrical components, Neha developed an automatic agri sprayer, using the Archimedes principle (a small force needed to exert a large pressure).

Mounted on a single-wheel cart, the automatic sprayer comprises a gearbox, DC motor, lithium-ion batteries, suction and delivery hose, two gator pumps, junction box, connector, barrel, accelerator, and other components.

The sprayer comprises of many components - a gearbox, DC motor, lithium-ion batteries, suction and delivery hose, gator pumps, etc,

To build the sprayer, Neha placed two gator pumps facing each other and connected their pistons to the larger wheel of the gearbox. Once this wheel starts rotating, it allows one piston to get pulled, simultaneously pushing the other piston. She attached a smaller wheel to a battery-powered DC motor via a chain that powers the whole set-up. Once completely charged, the machine can be operated for five hours consecutively.

“The rest of the set-up is such that when the pumps exert pressure, the suction hose sucks and pushes it to the junction box, containing three outlets. Lastly, the pressure release valve enables the effortless diffusion of the Bordo mixture,” Neha explains.

Transforming the lives of farmers

Upon completion of the prototype, Neha approached around 15 supari farmers and requested them to use the machine, and provide feedback.

Forty-one-year-old Suresh P, a betel nut farmer residing in Puttur, used Neha’s invention to spray the mixture on his crop. According to Suresh, he found the machine extremely convenient, as well as cost-effective.

Suresh P, a betel nut farmer residing in Puttur.

“Earlier, I had to employ three labourers to spray the mixture. One to combine the constituents, one to move the lever and produce pressure, and another one to spray it. But, Neha’s set-up is automatic and noiseless. From hiring 15 labourers for three days for my three-acre farm, I needed only five of them for two days. I was able to save 30 percent of the labour cost,” he says.

Neha along with the agri-sprayer she developed.

Additionally, the sprayer also consists of an indicator (made with Arduino Uno, ultrasonic sensor, jumper wires, and beeper), that displays the level of remaining mixture in the barrel for farmers to plan their next refills.

At present, Neha is looking to make the automatic sprayer commercially available in the market at an affordable cost. For this, she is receiving mentorship from Laghu Udyog Bharati — an all-India organisation for micro and small industries in India.

Belonging to a family, where her grandfather and other ancestors were also involved in farming practices, Neha says,

“I want to ensure my invention reaches every betel nut farmer in the country. Professionally, I would like to become an Ayurvedic doctor since the concepts of ancient medicine, herbal treatments, and natural healing sciences have always intrigued me.”

Edited by Suman Singh