How Purna Gummies is bridging nutrition gap with its supplements

Founded by Dr Archana Gupta in 2021, Delhi-based Purna Gummies serves a vast customer base, with over three lakh monthly customers in India. It is targeting a revenue of Rs 150 Cr by year-end.

A diet lacking proper nutrients can lead to multiple deficiencies, which can lead to low energy, fatigue, hair loss, and sleep problems. Health supplements are crucial for adults to meet their daily nutritional needs, including vitamins, minerals, amino acids, and plant extracts. According to a study by Scientific Diagnostic Center, 70% of urban Indian women are deficient in Vitamin D. Furthermore, these deficiencies can also impact the well-being of babies when pregnant women experience them.

To address these nutritional deficiencies, was established in 2021 by Dr Archana Gupta, a gynecologist with 35 years of experience.

In her role as a gynecologist, Gupta observed that many of her patients needed to take supplements like iron, vitamins, and minerals for extended periods. However, due to the unpalatable taste and odour of these supplements, patients often discontinued their usage, resulting in deficiencies and related health issues.

Gupta was determined to find a more appealing solution to address these deficiencies. This led to the founding of Purna Gummies, which manufactures nutraceutical gummies mainly focused on women in their 40s where such deficiencies are prevalent.

“This specific demographic of women required dedicated attention for a healthier society, and this was the driving philosophy behind the launch of Purna Gummies,” says Dr Gupta.

She further adds that a food supplement is exactly what its name denotes, a supplement. Its consumption has to be supplemented with a good diet, proper sleep, basic exercise, and 3 to 4 liters of water to see the best results.

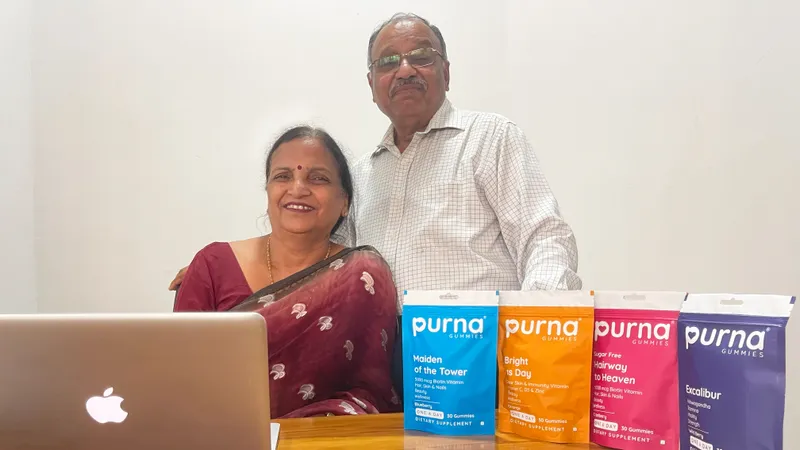

The company’s inception was a collaborative effort, with her husband, Rakesh Kumar Gupta, an electrical engineer, overseeing the setup of machinery, and her son, Apoorv Agarwal, a chemical engineer, managing formulation and quality control.

Archana and Rakesh Gupta

Purna Gummies was started with an initial investment of Rs 4 lakh. In FY23, the company achieved a revenue of Rs 20 crore. By the end of September in the current fiscal year, the revenue surged to Rs 45 crore, with an ultimate goal of reaching Rs 150 crore by year-end.

Purna serves a vast customer base, with over three lakh monthly customers in India and approximately two lakh customers in Europe and Africa. The company provides white-labeling services to five Indian and three international brands, while selling directly to consumers through online channels. Its workforce of around 200 employees covers production, packaging, R&D, quality control, HR, accounting, marketing, and sales.

Differentiating factors

Based on findings from Expert Market Research, the Indian market for vitamin gummies reached a value of Rs 58.3 crore in 2023. Driven by the rising awareness about the importance of consuming adequate nutrition, the market is further expected to grow at a CAGR of 31% during the forecast period from 2024 to 2032. By 2032, it is likely to achieve a market value of approximately Rs 549 crore.

According to TechSci research report, some of the major companies operating in the space include Power Gummies, Hindustan Unilever, Marico, and Mankind Pharma, among others.

Purna Gummies distinguishes itself through its unique manufacturing process, setting it apart from other gummy brands by focusing on enhancing taste and effectiveness.

The company’s delayed heating process results in smooth texture of gummies. This approach differs from traditional high-temperature drying methods used by many competitors, preserving the potency of active ingredients and preventing bitterness, says Agarwal, the Chief Marketing Officer at Purna.

One of Purna's primary focus is bioavailability, ensuring that the listed quantity of ingredients such as vitamins (in multivitamins, Vitamin C gummies, biotin gummies, etc.) is present in each gummy after drying and packaging to maintain effectiveness.

“The major benefit of making gummies at a higher temperature is that the product doesn’t need drying and can be packed immediately,” he adds. But this also results in rough texture and less potency. Insufficient drying can also impact the shelf life of products and lead to them being moist. Purna emphasises proper drying, which may take up to eight days for specific products.

He says that typically gummies are produced at 90 degrees celsius, whereas Purna manufactures its gummies at temperatures as low as 30 degrees. This approach preserves the potency of active ingredients and allows accurate label claims.

Presently, the company has the capacity to produce 200 kg of gummies per hour at its manufacturing plant in Delhi, which it claims is the highest-capacity plant in India in the category of nutraceutical gummies. The facility holds certifications from several organisations, including the US FDA, FSSAI, GMP, ISO, non-GMO, HACCP, and APEDA.

“We manufacture a wide range of gummy supplements, including multivitamins, Vitamin C gummies, biotin gummies, apple cider vinegar gummies, ashwagandha, melatonin, biotin, collagen, and more,” says Gupta.

Purna has around 40 variants in different flavours. It also offers sugar-free products. The company primarily distributes online to meet and expand its growing demand, available on platforms like Nykaa and Flipkart.

Future plans

Purna has ambitious plans to establish a new facility in Faridabad with a production capacity of 2,000 kg per hour. “This will make us the manufacturer with the highest capacity in Asia. Currently, the highest capacity in Asia is of a plant in China with a capacity of 600 kg per hour,” says Agarwal.

Manufacturing at Purna

The machinery for this new plant is being developed in-house by Rakesh Kumar Gupta, Co-founder and Technical Head at Purna, and his team of engineers.

“We are also planning to convert specific cosmetic products like Ceramide, Rosemary Oil, Glycolic Acid, Hyaluronic, Retinol, and Vitamin E into edible gummies. This product line is currently in the research and development phase,” says Dr Gupta.

Purna is also working on acquiring an Ayush licence to introduce Ayurvedic offerings and is developing sugar-free alternatives to accommodate various dietary preferences.

Additionally, it is in the process of obtaining a drug licence for hormone gummies.

Edited by Megha Reddy