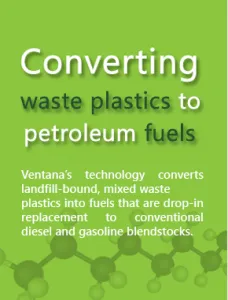

Amit Tandon's journey with Ventana to convert waste plastic into useful fuels

Amit Tandon is founder and CEO of Ventana – a company which has developed technology for conversion of waste plastics to petroleum fuels similar to diesel and gasoline. A greentech entrepreneur and a passionate engineer, Amit has authored five patents in this field and leads a team which today is at the forefront of solving one of the most thorny challenges within waste recycling – the challenge of recycling waste plastics.

The journey

Globally, almost two-thirds of waste plastics are land-filled or littered every year. In the last few years alone, littered plastic choked underground sewers which resulted in floods in Dhaka, Mumbai, Manila and elsewhere. So, when Amit first came across the possibility of recycling waste plastics to generate useful fuels in 2006, the solution greatly intrigued him. “I was awed by the fact that the concept offered twin benefits - of diverting landfill bound wastes and generating renewable fuels from it. Here was an opportunity for a win-win, to do good while doing good,” he says.

Amit spent the next several years researching and studying the underlying depolymerization technology that enables the conversion process. “I love to deconstruct large engineering problems to smaller bits,” he says “and I can be tenacious - very tenacious at doing this”. Most research work in the field at that time limited itself to arcane laboratory models and wherever larger conversion systems had been attempted, they lacked financial economics and had to be eventually shutdown. “Such systems deployed intensive batch based processes to generate lower economic value synthetic crude, slurries and petroleum waxes. The numbers just doesn’t work out on such systems, howsoever you do the maths” Amit says.

The field also suffered from “a high noise to signal ratio” - with many protagonists and scientists claiming shovel ready, zero emission technologies with secret proprietary chemical catalysts as their main ingredients . “It took me several years to chase down such hogwash claims and see them for what they were,” says Amit. However, the work during this time also helped him understand the significant complexity of developing and scaling a usable technology in this domain, as also the business model shifts that were needed to ensure risk mitigation across various stakeholders - from feedstock suppliers to fuel offtakers.

The plunge

In 2009, after a few years of intensive research in this domain, Amit faced a binary choice – to exit what was largely a promising but underdeveloped sector or to do the opposite - dive in deep to develop and deliver a cost-effective, fully continuous depolymerization technology which would take waste plastic and directly convert it to petroleum distillates. “It was a tough call – the risks were largely incalculable at that time – it wasn’t like we had a clear line of sight from where we were to where we wanted to be. We were chartering unknown waters and with technology development such as this you can only see so far before you hit a corner.” However, there were also some key favourables going for him, which he cites:

- I was wonderfully supported by my family, who have a generous belief in my ability to throw myself consummately behind things that drive me.

- It helped that I’ve the instincts of an engineer – I love to telescope arcane technical problems and had developed a good understanding of the engineering bottlenecks with pre-existing variants. I had some thoughts as how these challenges may be addressable.

- I come from a family of entrepreneurs and it was very synergistic for this effort to be incubated inside our current business – which is related to mechanical engineering and manufacturing. So, instead of asking - how do we slay this Goliath wholesale - we followed an ‘affordable loss’ approach – earmarking a financial budget and outlining technology goals that were needed to be achieved using such money.

Working with a few expert engineers borrowed from the parent company, Ventana designed its first generation pilot for conversion of waste plastics to fuels in 2009 and commissioned the same in 2010. It has since, commissioned two more pilots at its R&D centre near Chandigarh and in late 2012, commissioned a 3rd generation plant which implemented a fully continuous process for direct conversion of waste plastics to distillates similar to diesel and gasoline. The plant has run successfully for several months and Ventana has filed for multiple international patents on their IP. The company has also obtained determination from a US-based environmental firm that the technology meets stringent USEPA emission norms and produces 4 -8 X energy in calorific terms (in resultant fuel) than what it consumes in the form of electrical energy from the grid.

Amit says that this wouldn’t have been possible without his teammates, including Siddharth Mohan, Ashish Singhal , Rakesh Dutta and Biresh Thakur - who bring deep experience with chemical, mechanical, electrical and process engineering and come from leading engineering institutes such as IIT and Wayne State (USA). “Many of my current teammates left greener prospects in Fortune 500 companies to work on this – for me they’re the real behind-the-scene stars here,” he says.

The road ahead

Asked as to what motivates them, Amit says - “Most regions of the world have a 70-95% rate of recycling for waste paper, cardboard and metals. However, plastic recycling almost everyplace is at a much lesser rate. With plastic to oil technology, we believe this sector is poised for a disruptive change – and Ventana has a real chance to play a leading role in making this happen. Who wouldn’t want to be a part of that?”

Ventana’s development partners include Mott MacDonald (design engineering), Environmental Strategy (Philadelphia, permit engineering) and Indigo Energy (Atlanta, fuel offtake) and is on the starting line to commercialize the technology and give it scale.

Website : www.ventanacleantech.com