aha!3D: The bootstrapped story of Jaipur-based industrial grade 3D printer makers

Aakash, a gold medallist of MNIT Jaipur 2002 batch got a taste of entrepreneurship when he joined Vihaan Networks in 2005. Before that, he had two smaller stints with C-DOT and Mentor Graphics. A curious mind, Aakash always had pet projects he’d work on. While working on his projects, he became aware of the limitations of conventional mechanical prototyping. Around 2009, he came across the RepRap project which had begun as an initiative to develop a 3D printer that can print most of its own components and be a low-cost 3D printer. This really spiked his interest and in 2010, he decided to start his own company AHA Gadgets which was later rebranded to aha!3D.

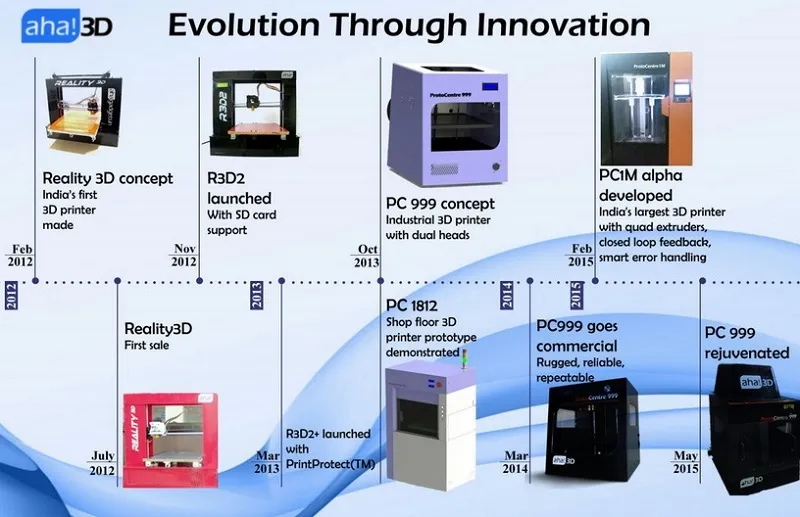

The idea was to develop indigenous 3D printers dedicated to the needs of Indian market. “Our first product Reality 3D, which also became India’s first indigenous 3D printer, was appreciated a lot at various platforms. The scope in this field motivated us to take this as full time work,” says Aakash. Aha!3D specialises in industrial 3D printers with a focus on reliability, repeatability, and ruggedness. The company also provides 3D printing services to customers wherein people can send their designs to get them prototyped.

Aha!3D has two products in the market, one catering to the desktop 3D printing segment and another to large-build volume shop-floor 3D printing segment. Their ProtoCentre 999 is the desktop 3D printer with a build volume of 9x9x9 cubic inches. It is a desktop model and comes with all features to provide an industrial quality output. “It comes with all metal chassis, closed chamber heated bed assembly with dual extruders. It has a printable range of materials including ABS, PC, HIPS, PLA, PETT and Nylon, apart from newer special materials like brassFill, woodFill, and other composite materials,” says Aakash.

And the ProtoCentre 1M alpha was introduced as a pilot product with selected technical partners (build volume of 30x20x40 inches cube, quad water cooled extruder and state of the art control software). “There are various low cost 3D printer available in market but they have too many limitations which are not acceptable in professional grade machines. Our entire research is dedicated to provide viable industrial grade machines, offering unparalleled return on investment,” says Aakash.

All aha!3D parts are made in India and the team follows a “soft inventory” concept where they keep digital designs for 5% parts which are 3D printed just-in-time when needed.

Completely bootstrapped, aha!3D is proud to call itself “customer funded”. Adobe India bought Reality3D, the first version of their 3D printer when Adobe was in the process to develop a postscript equivalent for 3D printers. ISRO’s team which worked on the Mangalyaan also bought a PC999. They use it for making prototypes to test and validate their designs of the mechanical components. DRDO’s MTRDC Bangalore lab, which researches on microwaves, also bought PC 999 from aha!3D. “Our customers have graciously given us problems to solve and trusted our team to come up with the right solution,” says Akash. The desktop printer comes with a price tag of Rs 2,00,000. The industrial version is a custom made printer which is designed according to the demand of customers. Apart from selling 3D printers, the company also makes money from the 3D printing services it provides.

3D printing has attracted a lot of attention globally. With over $100 million in funding, Carbon3D is a benchmark company in the space and Shapeways, another upcoming giant in the space raised $30 million in July this year. Back home in India, Fracktal Works raised a round at $3 million valuation, there are other companies like df3d, Global3D, etc., making headway. For aha!3D, it has been an exciting journey. Their team has expanded to 12 members and consists of experts on all aspects of machine design. Talking of the road ahead, Aakash says, “We are introducing a new application of 3D printing for the Indian scenario. We want to be the reason for adoption of 3D printing in mainstream life of India and also get India recognised for fundamental innovation on the global map.”

Website: aha!3D