This food processing solutions company is making production effortless; counts ITC, Haldirams as clients

Started in 1984, Noida-based Kanchan Metals is an importer, manufacturer, and seller of food processing equipment in India. It has around 1000 companies as part of its clientele.

The Indian food processing industry has enormous scope for growth in the coming years. According to a report by Invest India, this sector is expected to reach $535 billion by 2025-2026.

Moreover, companies wanting to provide increasingly cost-effective, yet quality products has further paved the way for innovation and disruption in this sector.

One of the companies that has carved a niche for itself is .

The Noida-based company is an importer, manufacturer, and seller of food processing equipment in India. Started in 1984, it has around 1000 companies in its clientele including leading FMCG companies like Britannia, Bikanerwala, Haldirams, ITC, and several small and medium food businesses as well.

This week, SMBStory got in touch with Kanchan Metals’ Director and third-generation entrepreneur, Raghav Gupta, to chart the growth of the company over the years.

From metals to food

Kanchan Metals, as the name suggests, started as a trading company for ferrous and non-ferrous metals in 1984 by Raghav’s grandfather and father, Sanjeev Gupta. The company was headquartered in Kolkata at the time. In the 1990s, the team wanted to diversify into other categories and started scouting for opportunities to explore.

Around 1996, they found an opportunity in the food processing industry equipment space.

“In those times, FMCG companies were desperate to ramp up production-related technologies and increase capacities. They required equipment of a particular category which were not easily available in India,” says Raghav, adding that Kanchan Metals then decided to start supplying food processing machines to Indian food companies.

Gradually, it transitioned completely into this new model and moved away from the trading of metals.

The company began by importing machines for making snacks and gradually diversified into other categories like bakery, frozen foods, namkeen, instant foods, etc.

In 2012, Kanchan Metals went through a turning point with some key developments like becoming a contract manufacturer for ITC Limited.

Moreover, it opened a new facility in Greater Noida for manufacturing packaged snacks under ITC’s label. This was also the year when the company shifted base from Kolkata to Noida.

“We gained confidence as now we were not just trading the equipment but also manufacturing the products ourselves,” highlights Raghav.

These small wins contributed towards building Kanchan’s robust business model, which today includes importing equipment from the US, Japan, Europe and other countries, manufacturing equipment (individual equipment and complete product lines) and lastly, contract manufacturing.

The company also provides entire turnkey solutions for the imported equipment including packaging equipment, maintenance and after sales support services.

In terms of price, the machineries cost more than Rs 50,000 and go up to Rs 6 crore.

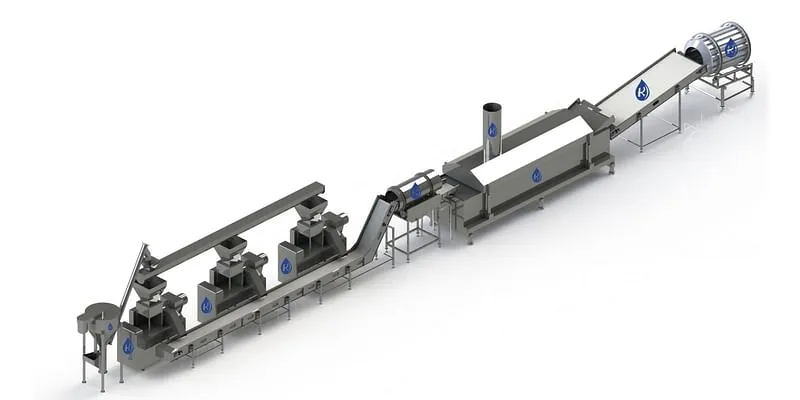

Kanchan Metals' complete line for making fried collets

Growth strategy and staying relevant

Raghav says that the company has grown primarily because of being “debt-averse” and having a “conservative approach.” The company has taken loans but mostly invested the profits to grow and expand the business.

“If you see Apple, it sells simplicity and science. Similarly, TATA sells trust. We, as a company, position ourselves as a solutions provider for anything and everything under the umbrella of food product equipment,” he explains.

The company has also relied extensively on customer feedback, and this has enabled them to innovate and grow as a company.

For instance, about two years ago, Raghav shared that there was a growing demand for vegan meat products equipment in the market. “Sustainability is a big thing now. People want products in which animals are not harmed, and are plant-based.”

Raghav remarks that while this trend was already popular in the West, it was gaining steam in India as well. That is when Kanchan Metals introduced a vegan meat processing machinery in the India market imported from the US. The demand for this machine has grown a lot, and Raghav claims that today it is one of the company’s major products.

Recently, it also launched a Pellet Frying Line (for namkeen like sabudana, vatana, etc.) and an intermittent vertical tray lifting system.

Reimagining the future

Raghav says that in the wake of COVID-19, the demand for processed food machinery has grown multifold. “There was a lot of panic buying wherein people wanted to keep everything at home especially frozen foods.” According to a report by IMARC, the market for frozen foods markets has been witnessing a splurge “owing to their convenience as they do not need any additional preparation and culinary expertise.”

Amid the nationwide lockdown, even startups like Licious, iD Fresh Foods, and Grofers, among others, reported an increase in the sales of ready-to-eat and frozen foods categories.

Raghav says he is expecting the revenue to double in this fiscal year owing to this trend. Going forward, the company is planning to set up a “demonstration facility” wherein companies can see how machines work, test and inspect them before buying them.

“International travel will not be the same as it was before so this facility will help customers who want to deploy imported machinery.”

Referring to automation, Raghav adds that the company is focussed on introducing products that make production “less-labour intensive.”

“Automation is happening in every field in the world today. We want to partner with companies in company automation and, in parallel, develop our own expertise in this area,” he concludes.

Edited by Anju Narayanan

-with-the-team.png?mode=crop&crop=faces&ar=16%3A9&format=auto&w=1920&q=75)