Wonder Grass: Using bamboo to provide a low-cost solution to India's housing problem

Bamboo is one of the oldest and most versatile materials used for construction of houses and other structures. As a building material, it is relatively inexpensive, easy to work with and readily available in most countries where bamboo grows, besides providing a service life of up to 50 years. The importance of this tree for the construction sector has received increased attention in recent years, as shelter for the homeless continues to be a serious problem throughout the developing world. In India, it is estimated that there will be a shortage of 39 million dwelling units by the end of this century. Also, the steady growth in population has increased pressure on availability of conventional building materials.

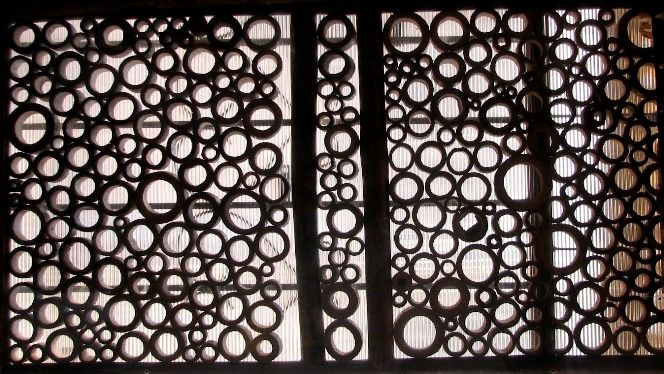

In order to bring bamboo-based building system in the mainstream of construction-industry and spread its various benefits, Wonder Grass is creating a range of pre-fabricated structural components. They include everything from columns, panels, screens, and walls to interior accessories and entire houses. “Bamboo can bridge the gap of building requirements in India. We are the second largest bamboo growing country after China, it grows fast and is available in abundance almost everywhere across the subcontinent”, says Vaibhav Kaley, the founder and brains behind Wonder Grass.

The greatest inspiration and motivation to start the six-year-old company came from his father, Vinoo Kaley, an architect known as “Bamboo man” who intensively believed in the potential of this grass, researched it extensively, and worked with several rural artisans. Vaibhav followed his father’s steps and graduated in Interior Design, following it up with a post-graduation in urban projects from Bauhaus University, Germany. Today, he focuses on producing mass housing and living units for the hospitality sector.

Wonder Grass was incubated at the NS Raghavan Center for Entrepreneurial Learning at the Indian Institute of Management in Bangalore. The bamboo manufacturing happens in Nagpur, which is known for its dense bamboo forests, where Wonder Grass employs 25 artisans. Over the next few months, Vaibhav expects to launch showrooms in Bhubaneswar, Chennai and Pune, where customers can get acquainted with the different uses of bamboo in the construction sector.

“People are still apprehensive about bamboo buildings. They ask ‘Will it be safe?’, ‘Will the structure be strong?’. First, bamboo has to start becoming part of their living so people can get familiar with this system and how to introduce it into their daily routines, but it is already possible to see the opportunities for other building materials to come in”, remarks Vaibhav. According to him, brick-and-mortar houses are something people aspire for, but they are extremely energy-consuming, non-biodegradable and hostile to the environment.

Of all the advantages of bamboo housing technology, the most important is that its low-cost without sacrificing quality and durability. A 400 sq ft house in a village, which costs Rs. 1.75 to Rs. 2 lakh with conventional materials, can be built for Rs. 1.25 lakh if bamboo is used. Furthermore, a bamboo house takes very little time for assembly. This becomes critical especially in times of disaster management, providing quick relief or rehabilitation.

Vaibhav foresees a day when rural communities will become self-sustainable through bamboo. “If rural villagers learn the required skills and set-up a micro-enterprise, they will not only be able to build houses for themselves, but for others as well. The material [bamboo] will be available within the vicinity, they won’t have to get cement from somewhere else, and the dependence on external factors will come down. Besides housing, there are different applications for bamboo structures in a typical rural community: it can be a place for dairy stocks, cows, a small community center… anything”. He says that now the company has made good progress. “From the past two years there has been a good traction that will lead to faster growth”.

Benefits of bamboo

Absorbs carbon dioxide and releases 35% more oxygen into the atmosphere than hardwood trees. Also, no fertilizer, pesticides, or herbicides are needed.

Generates very little waste: after harvesting, virtually every part of the plant is used to make a wide variety of products, from soil-enriching mulch to furniture to chopsticks.

Versatility: bamboo can replace the use of wood for nearly every application. Paper, flooring, furniture, charcoal, building materials and much more can be made from bamboo. Also, its fibers are stronger than wood fibers and much less likely to warp from changing atmospheric conditions.

Safety: due to its light weight and favorable elasticity, the ability of bamboo to resist earthquake pressure is very good.

Comfort: people prefer bamboo houses in rural tropical areas where the temperature is high in summer.

Technology: requires minimum technology. Most bamboo houses are based on local technology, which does not require high complexity in its construction. Its versatility offers many technological options and is very economical.

Durability: with proper treatment bamboo provides service life of up to 50 years. Durability can be increased with careful choice of bamboo species, preservation, and use of complementary construction materials and replacement of outdated or deteriorated parts in a regular basis.

Soil protection: Bamboo roots remain in place after harvesting where they prevent erosion and help retain nutrients for the next crop.

Get to know more about Wonder Grass and bamboo housing by clicking here