Improved, heavy rare earth-free, low-cost magnets for EV vehicles could reduce mobility costs: Report

Nd-Fe-B magnets used in EVs operate at high temperatures of 150–200°C and need to exhibit high resistance to demagnetisation, a capability that pure Nd-Fe-B magnets do not have.

Scientists have fabricated improved low-cost, heavy, rare-earth-free high-Nd-Fe-B magnets, which are in high demand for electric vehicles and can make them more affordable.

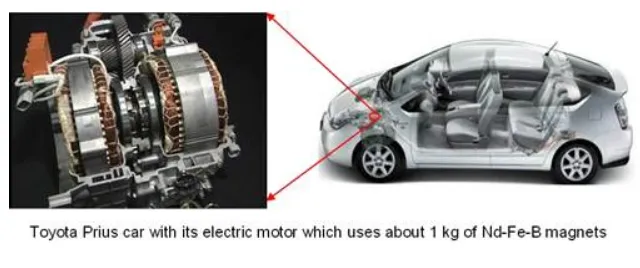

More than 90% of EVs use brushless DC (BLDC) motors made up of rare-earth Neodymium Iron Boron (Nd-Fe-B) magnets.

Nd-Fe-B magnets used in EVs operate at high temperatures of 150–200°C and need to exhibit high resistance to demagnetisation, a capability that pure Nd-Fe-B magnets do not have. Hence, dysprosium (Dy) metal is added as an alloy to improve the resistance to demagnetisation.

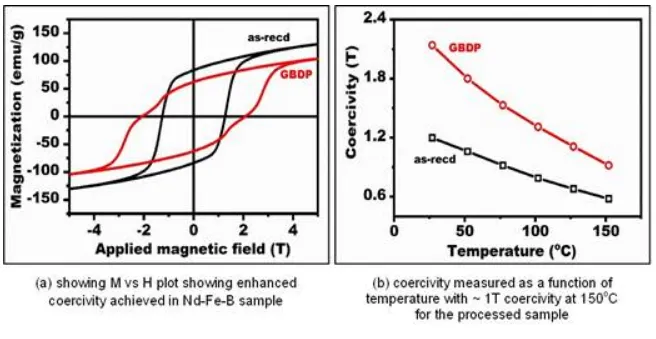

Researchers all over the world are attempting to improve the coercivity (resistance to demagnetisation) of NdFeB magnets without the use of expensive Dy. A strategy adopted by the research community to enhance coercivity is to enrich the region between the grains of the Nd-Fe-B magnet with "non-magnetic" elements through suitable heat treatments (grain boundary diffusion).

Since its discovery by Sagawa in 1984, the Nd-Fe-B magnet has been one of the most sought-after permanent magnetic materials for many applications due to its exceptional combination of magnetic properties.

Recently, scientists from the Centre for Automotive Energy Materials at the International Advanced Research Centre for Powder Metallurgy & New Materials (ARCI), an autonomous Research and Development Centre of the Department of Science and Technology (DST), Government of India, have enhanced the coercivity of Niobium (Nb)-containing Nd-Fe-B melt-spun ribbon by grain boundary diffusion process (GBDP) using a low melting point alloy of Nd70Cu30 which acts as the source for the "non-magnetic" element.

They have reported restricted grain growth during grain boundary diffusion due to the precipitation of Nb, which facilitates the enrichment of copper (Cu) at the grain boundaries, aiding the increased resistance to demagnetization of Nd-Fe-B powders. The coercivity value of 1 T at 150oC critical for automotive applications, achieved in this research published in Materials Research Letter could be a useful strategy to develop magnets without Dy for EV applications.

ARCI has ventured into the setting up of a pilot plant for the manufacturing of near-net-shaped Nd-Fe-B magnets through a major project funded by the Science and Engineering Research Board (SERB) in line with the Atmanirbhar Bharat mission of the Government of India. The strategy mentioned will be explored for magnets manufactured in the pilot plant.

The new strategy could also be used for commercial production of Nd-Fe-B magnets in India, reducing imports that meet the major requirements of the automotive sector.

Edited by Teja Lele