How CEAT reimagined its infra for the services economy

The transformation prepared the tyre-manufacturer for new business models.

After the first COVID-induced lockdowns in 2020, vehicle manufacturers in India were unable to resume production at normal levels. For tyre-manufacturer CEAT, the tyre-replacement opportunity began to look better than selling tyres to original equipment manufacturers (OEM) in the uncertain backdrop.

CEAT Managing Director Anant Goenka told equity analysts in January 2021 that the demand mix was typically 60 percent (replacement), 25 percent (OEM) and 15 percent (exports).

The Mumbai-headquartered company has 300 exclusive outlets (Ceat Shoppes) across India, apart from a network of 3,400 dealers. To expand the tyre-replacement opportunity, in August 2020, CEAT announced a partnership with ReadyAssist to enable roadside assistance services in Bengaluru and Hyderabad. The services included puncture repair, battery jumpstart, key unlock assistance, minor repairs, emergency fuel delivery, and towing.

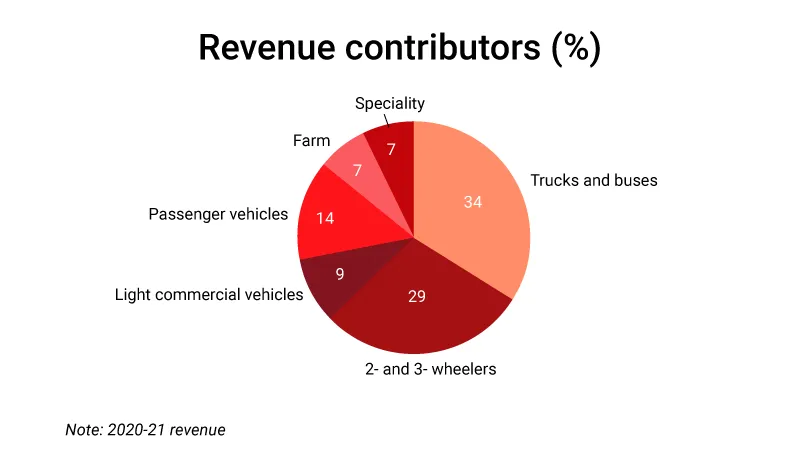

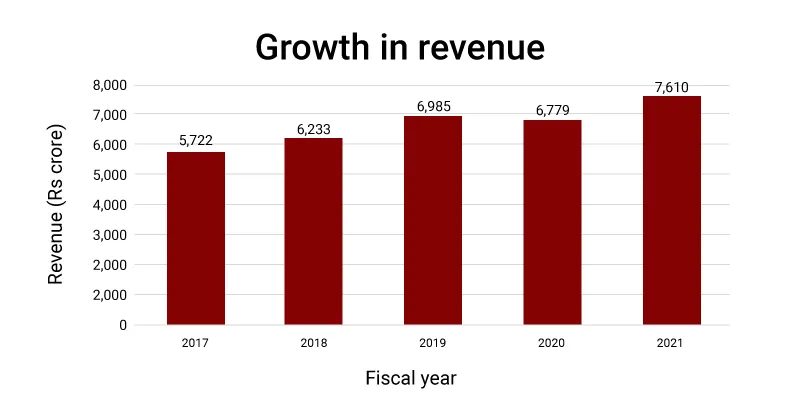

Further, CEAT has a 44.17 percent stake in Tyresnmore Online, an online service in eight cities to change bike and car tyres at a vehicle-owner’s location. The Rs 7,610-crore tyre manufacturer also has a stake in eFleet Systems that develops fleet management software for the logistics industry.

For a product manufacturer, CEAT has had to cultivate a services mindset to grow revenue. And, digitisation has proven to be vital in building a complete real-time view of the company’s operations.

Last year, the company took a technology tool live that tracks key accounts, with features like tyre-tracking and scrap-tyre inspection. But a lot of the hard work in modernising its technology infrastructure to enable such applications began in 2018.

Starting on a clean slate

In 2018, CEAT’s technology organisation had a choice to make: upgrade the existing infrastructure and processes as is—or start afresh. “Instead of a conversion, we adopted a greenfield approach,” recalled U C Singh, Chief Information Officer of CEAT, at the AWS Summit India Online. “We reviewed the entire process in a very different way, looking at the business realities.”

From an operations standpoint, Singh had to improve the lead time to roll out new applications, and run multiple projects at a time.

The needs were many and diverse, spread across departments: enhancing customer experience to interact with CEAT, optimising the plant capacity, managing the inventory, and so on.

There was a plethora of applications and systems to harmonise, such as the manufacturing execution system (MES) that tracks and documents the transformation of raw materials to finished goods, product lifecycle management applications for new product development, and a Salesforce tool for a customised dealer portal.

CEAT's distributors are connected using Botree software, and its supply chain runs on Blue Yonder. It was running a variety of enterprise applications.

With the management’s buy-in, Singh opted to move 70 percent of the compute workload to cloud. “Only files related to the drives reside on the premise,” he said. “Except the MES domain controllers, most of our infrastructure is now on the cloud,” Singh added.

Designed for the new normal

During the transformation, CEAT augmented the MES at two manufacturing plants with smart factory initiatives. It has seven manufacturing facilities.

The whole modernisation exercise took place in nine months, and was ready by 2019. Singh says CEAT is able to run more than 15 projects at a time, and the cloud infrastructure has enabled new businesses like tyre-as-a-service.

On the customer front, in July 2020, CEAT linked more than 200 of its CEAT Shoppes, so that vehicle-owners can resolve their problems at any CEAT Shoppe.

Last week, the company announced a tie-up with Tyresnmore to provide contact-less tyre-related services at customers’ doorstep. The services mindset is important when enterprises are accelerating growth in the API (application programming interface) economy.

“Any automation and digital initiative must improve the productivity of the entire value chain,” said Singh. “Unless we have a very strong digital goal, the journey would not have been fertile.”