From hiring cobblers to make four pairs of shoes, how this footwear company became a Rs 700 Cr brand

Liberty Shoes was started to liberate Indians from foreign products. What started by manufacturing just four pairs a day with the help of cobblers, now makes 50,000 pairs each day, and is recording an annual turnover of Rs 700 crore.

India is the second largest global producer of footwear after China, accounting for 13 percent of global footwear production, according to an MSME report. The footwear industry also generates maximum employment opportunities, especially for the weaker sections, and therefore is an important part of the Indian economy.

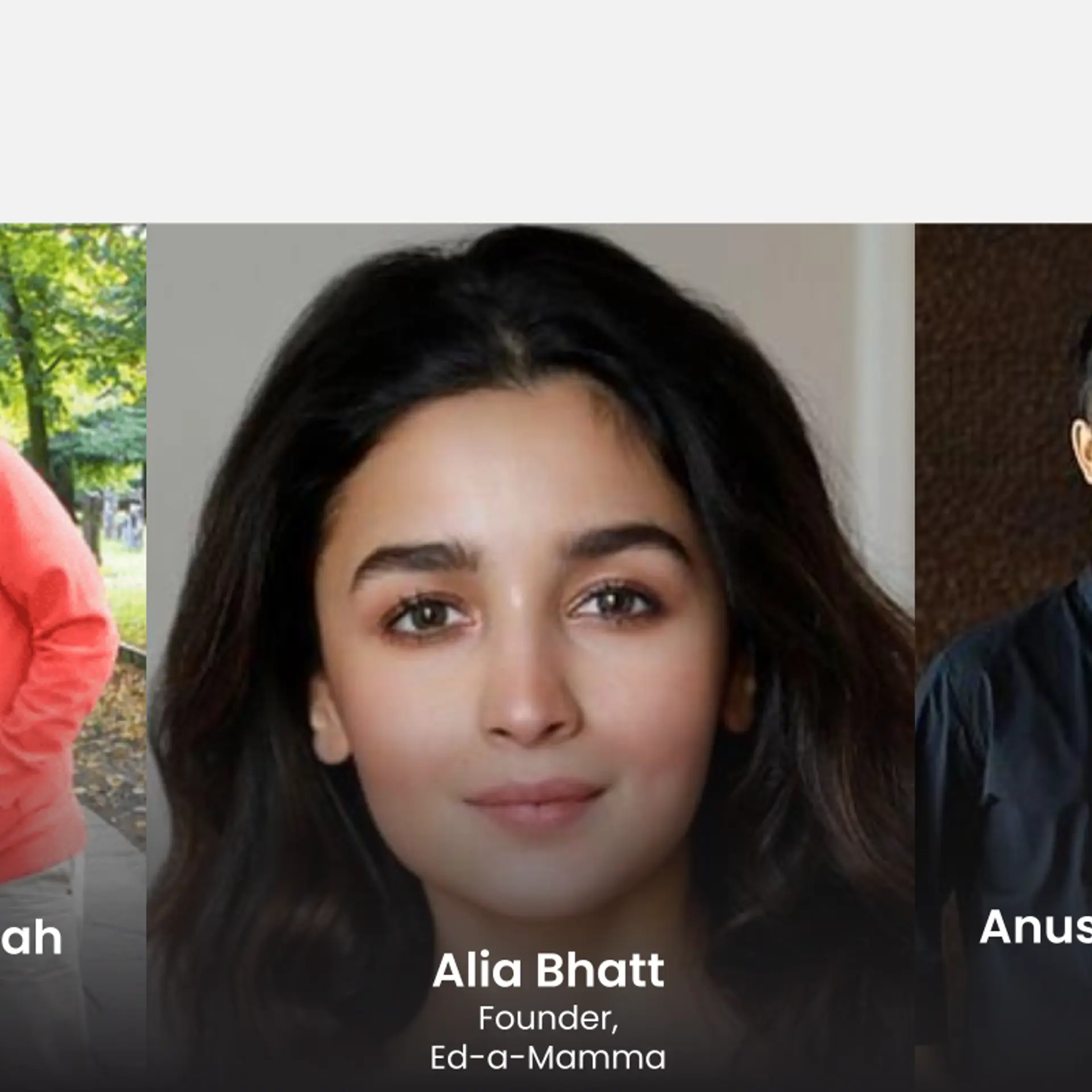

Anupam Bansal, Managing Director, Liberty Shoes

But just a few decades ago, the scenario was very different in India. People were more inclined towards international brands, and trusted more in products made overseas.

During this time, and a few years after India got independence from the British Raj, Dharam Pal Gupta, Purshotam Das Gupta, and Rajkumar Bansal joined hands to launch a domestic footwear company in 1955 with a vision to reduce dominance on the imports, and rely on the ‘Make in India’ footwear. They started a 500 sq. ft shop in Karnal, Haryana, and called it Pal Boot House.

“That time, Indians were dependent on foreign-made goods. My uncles and father wanted to create an employment opportunity for the lower sections of the society and liberate Indians from the stranglehold of foreign brands. Thus, they hired cobblers in the shop to start manufacturing shoes,” Anupam Bansal, Managing Director of Liberty Shoes, who is a second-generation entrepreneur, tells SMBStory.

The founders changed the name from Pal Boot House to Liberty Shoes keeping their vision aligned to liberate Indians from foreign dominance.

What started by manufacturing four pairs a day in 1955, today Liberty Shoes makes 50,000 pairs each day, and is recording an annual turnover of Rs 700 crore.

Anupam says, “The new generation prefers international footwear brands but it isn’t going to be long term. The Indian footwear industry is getting organised, and brands are growing significantly giving a tough fight to international players.”

From exports to retail

Liberty Shoes' leather shoes collection

When the trio started the company, they started selling shoes made in the shop with the help of cobblers. The same continued till 1964, after which they set up their first factory in Karnal itself.

Later, they decided to expand their market size by stepping into foreign trade. One fine day, Purshotam Das Gupta decided to visit the Trade Council Association to discuss the way ahead.

“On the way to the Trade Council Association, my uncle saw a person met with a small accident and helped him on getting to his vehicle. Later, he came to know that the person was from the Russian Trade Council, and was instrumental in processing the exports,” says Anupam.

This small incident changed their life completely, and they first started exporting to Russia. Later, they expanded their footprint to Hungary, Czech Republic, and Czechoslovakia. The exports continued till the early 80s when Russia disintegrated.

In 1984, they modified their business model and started focussing on the domestic market. They opened their first store in Kurukshetra, a small city in Haryana, and since then, there has been no looking back.

Liberty shoes primarily followed franchise and distribution business model and in 2004 started company owned stores.

The company presently produces 50,000 pairs of footwear a day through its four manufacturing units, two each in Uttarakhand and Haryana, sold through 6,000 multi-brand outlets, and has a presence in 25 countries, with 50 showrooms outside India.

In the years that followed, Liberty Shoes launched 10 sub-brands including Force 10, Fortune, Gliders, Senorita, Tiptopp, Windsor, Coolers, Footfun, Warrior, and Prefect. Recently, the brand forayed into the accessories segment, including leather bags (laptop bags, ladies’ bags, wallets); shoe care (shoe smile brand of polishes and cleaners); and footcare (perfumed socks). The company has also entered the lifestyle retail business with ‘Liberty Lifestyle’ and its range of perfumes.

The brand currently sources leather from Kanpur and other shoe accessories from Agra in India. Other raw materials are procured from overseas.

A pioneer in footwear technology

Liberty Shoes' sports shoe collection

Anupam claims that Liberty Shoes has been a pioneer in technology adoption in India by bringing various manufacturing technologies to its factories.

“Right from smile technology that massages acupressure points, we have memory foam technology, sweat-absorbing technology, and feel good four-time technology very useful for the feet,” he says.

Liberty believes in constantly focusing on improvising and innovating to come up with the best for its customers. The company emphasises on a comfortable and fashionable walk through technologies that make the shoes worth purchasing.

Industry and major challenges

Liberty Shoes' kids collection

With the rise in footwear manufacturing units across the country, the footwear industry in India is transforming itself towards being a more technically inclined and innovation-driven sector.

The market size is mostly dominated by the unorganised sector, and comprises Rs 600 crore approximately, Anupam says, adding the share is expected to rise by approximately two percent from the branded sector.

Speaking about the business challenges, Anupam says,

“Competition with other brands has never been a challenge. The prime challenge is to deal with the unorganised players and also the trade disparity.”

To keep pace with the ever-changing fashion and to live up to the expectations of customers, keeping up with market changes, deciding when to abandon a strategy and when not are the other challenges faced by the company.

Putting its best foot forward

At present, Liberty Shoes prefers committing to sustainability and concentrating on increasing the customer base.

The brand also has plans to enter the premium segment, and targets to reach a turnover of around Rs 1,000 crore by 2022.

(Edited by Megha Reddy)