MTAR Tech: How 2 engineers built a Rs 213-Cr revenue firm that builds engines and precision components for ISRO, DRDO, NPCIL

With MTAR Technologies making its market debut at over 80 percent premium, Managing Director P Srinivas Reddy tells SMBStory how two engineers built the firm into a leader in the precision engineering space with revenue of Rs 213 crore and top domestic and foreign clients.

Precision engineering company MTAR Technologies’ origin dates back to 1970, when it was established by two friends and technocrats P Ravindra Reddy and the late K Satyanarayana Reddy.

Its first project was the manufacture of coolant channel assemblies for nuclear reactor cores, as sought by the Department of Atomic Energy at that time.

The department had first approached state-owned HMT Ltd (then Hindustan Machine Tools Limited) for the project, but it declined, saying there was too much complexity involved.

So the Reddy friends took up the challenge. With four machines at a small workshop in Hyderabad, they started MTAR. A year later, Ravindra’s brother, PJ Reddy, joined the company to handle its finances.

Since successfully executing the first project, MTAR has extended its vision to indigenise manufacturing for nuclear, defence, and space sectors.

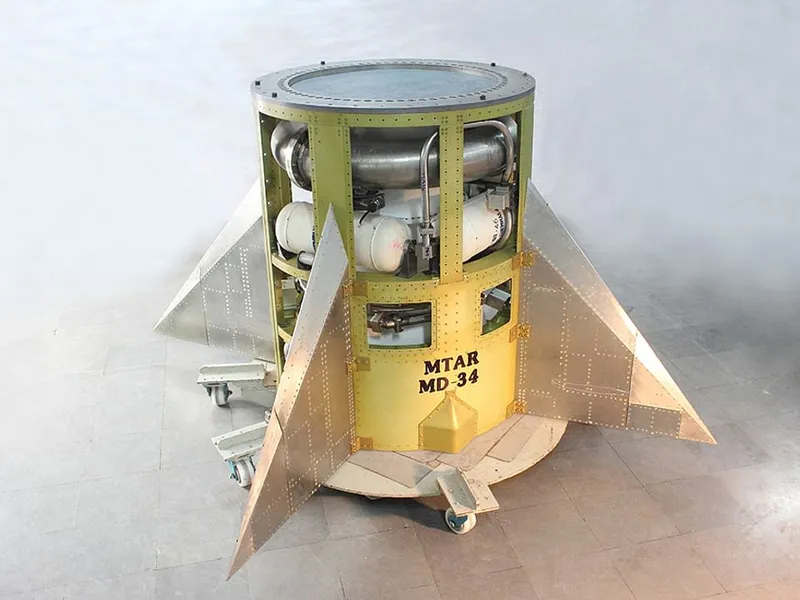

Base shroud assembly for Agni program

Today it is a leader in the nuclear, defence, and aerospace equipment space, with domestic clients such as , Nuclear Power Corporation of India Limited, and Defence Research and Development Organisation, and overseas ones such as , Dassault Aviation, and Elbit Systems.

“We have over 400 machines, including 160-plus CNC (computer numerical control) machines spread across seven units,” says P Srinivas Reddy, Managing Director and Ravindra Reddy’s son. “In FY 2020, our revenue from operations was Rs 213.8 crore, our order book size was Rs 345 crore, and our gross profits were 66.2 percent.”

In an exclusive interview with SMBStory, Srinivas Reddy talks about how the founders built one of India’s premier defence, space, and nuclear manufacturing companies.

Edited excerpts:

SMBStory [SMBS]: What were the first few years at MTAR like and how has the business grown?

P Srinivas Reddy [PSR]: Back in the 1970s, India’s manufacturing sector was in a nascent phase and there was a need to indigenise many technologies in sectors such as nuclear, space, and defence.

There wasn’t much support, so MTAR’s founders co-developed and supplied complex products such as fuelling machine heads, bridges and columns, drive mechanisms, and grid plates for the core of nuclear reactors; liquid propulsion engines, cryogenic engine assembly, etc. for space launch vehicles; and base shroud assembly for the Agni programme in defence.

We built ourselves into a one-stop solution for all manufacturing needs such as advanced machining, specialised fabrication, assembly and testing, heat treatment, special processes such as painting and surface treatment, and quality control. The firm has grown into what it is today through internal accruals.

SMBS: How did the company diversify into different manufacturing categories?

PSR: We started in the nuclear sector with the project for the Department of Atomic Energy and later diversified into space as we found a need to indigenise the technologies used there. We then ventured into defence when there was a need to cater to Agni.

Nearly a decade back, we forayed into clean energy considering the global need to develop products that reduce carbon emissions.

At MTAR, we have always developed our product portfolio based on the critical engineering needs of national as well as global customers.

A Vikas engine made by MTAR for satellite launch vehicles

SMBS: Where does the manufacturing take place?

PSR: We currently operate seven manufacturing units, of which three are supporting units and the other four profit centres. We are in the process of establishing an additional manufacturing facility at Adibatla in Hyderabad, which is expected to become operational in FY 2022.

This will be a sheet metal facility, which shall allow us to undertake sheet metal jobs for Bloom Energy, ISRO and some other customers.

We are also planning to construct an additional shed for specialised fabrication to supply products to our domestic and international customers.

SMBS: What are some of the challenges the company has faced?

PSR: The initial challenge was to set up the capabilities required for the development of a product in strategic sectors and the second was the development of products. To address the first challenge, our founders built many machines in-house, instead of importing similar ones from abroad, which has resulted in a lot of savings for the company.

We have built some of the sophisticated, in-house special purpose machines (SPM) such as SPM-99 and Gantry SPM used for various special operations.

Once the facilities were developed, the challenge was indigenising the technology and developing the end product. It was a roller coaster ride as our engineers spent several hours on the shop floor carrying out R&D (research and development) to come up with certain products.

It took many years of efforts to develop the products that we supply today. We are maintaining the same pace to develop future technologies. We strategise three-four years ahead of time to develop a new technology.

For instance, we have completed the development of electro-pneumatic modules this year, for which the developmental activity started in 2016.

SMBS: What is special about MTAR’s products?

PSR: The products manufactured by MTAR have a tolerance of about 5-10 microns (1 micron=0.001 mm). The products require critical tolerances as they go into nuclear reactors and space launch vehicles, where failure is never an option.

The quality norms are stringent and we haven’t faced a single blemish till date. Criticality and quality are the aspects our products stand for.

While our strengths overlap with some of the players in some sectors, the kind of capabilities we have in the precision engineering space is unique. We have built our strengths and adapted to market needs.

To integrate our production, supply chain, and finance functions and meet our ERP (enterprise resource planning) needs, we use Microsoft Navision. We customise some of the features of ERP as and when required.

Assembly and testing at MTAR

SMBS: How did the company survive the lockdown and go for an IPO?

PSR: The pandemic posed intense challenges due to lockdowns across the nation, but due to rigorous planning we still exceeded our targets for the first three quarters.

When there were lockdowns at customer sites and we were not able to get free issue materials, we expedited orders where the procurement of material is involved and deferred free issue material orders.

Also, our robust supplier base has helped to procure raw materials from an alternative vendor, in case a certain vendor faced any challenges due to COVID-19.

We have gone for an IPO as we want to repay approximately Rs 50 crore of debt incurred and also need funds to meet increasing working capital requirements. This is in view of future growth, so that our internal accruals can be utilised for establishing new capabilities.

SMBS: What are the plans now?

PSR: We intend to increase our wallet share in the sectors we cater to by taking up volume production for developmental orders and at the same time enhance revenues from products that are already into volume production.

We intend to maintain a healthy mix of developmental-volume production and take up the developmental activity of new technologies.

Edited by Lena Saha