From building materials to textiles, sustainability drives this 40-year-old company

Started with savings of Rs 5 lakh, Hyderabad-based Visaka Industries has a turnover of Rs 1,127 crore on its product range of solar roofing, plywood substitutes, and PET bottle-recycled yarn.

Companies that innovate are companies that shine and stand the test of time. Hyderabad-based Visaka Industries Limited is one such company.

Set up as a cement roof-manufacturing company in the early 1980s by G Venkat Swamy and his son G Vivekanand, it has transformed over four decades to make sustainable building materials and textiles, and record an annual turnover of Rs 1,127 crore in 2019-20.

In an interaction with SMBStory, third-generation entrepreneur and Joint Managing Director Vamsi Gaddam recounts the vision of his father and grandfather, and how he has carried that forward.

“My grandfather and father took the company to great heights, and I was predestined to join the family business,” says Vamsi. “I joined in 2008 and had one core vision — to make Indian products known globally.”

In the early 1980s, Venkat Swamy wanted to set up a business that could employ people from economically backward classes. But prior to the economic liberalisation of 1991, it was hard to get a licence to start a business.

The construction industry was booming in India at that time and had a lot of a potential to contribute to the economy. This interested Swamy and he approached his son, who was pursuing MBBS from Osmania University. Vivekanand decided to help his father pursue his dream.

Swamy invested Rs 5 lakh out of his personal savings and got some money from the Andhra Pradesh Industrial Board to start Visaka Industries Limited.

Today, it is an NSE and BSE listed company with a pan-India presence and major international clients.

Early pivot

Visaka started with manufacturing cement roofs, sourcing and producing everything locally, yet it became sensitive to environmental concerns early on. In 1992, the company expanded into textiles, developing the revolutionary sustainable fabric, Wonder Yarn, from discarded PET bottles. The technology of Murata twin air-jet devices integrates the material used in PET bottles to create a fabric that has since kept 100 million PET bottles from being dumped into landfills.

In 2008, when Vamsi entered the business, he did not want Visaka to be seen only as a producer and supplier of goods.

“The Indian market lacks being vocal about its products,” he says. “At a global level, we don’t have many leaders from India, who are doing great in the business. I joined the business with an aim to be more vocal about our products.”

A substitute for plywood used in construction- Vnext

After Vamsi’s entry, Visaka introduced a brand that would manufacture a range of sustainable building products and be a substitute for plywood. The main products under the Vnext brand are Vnext Board, Vnext Premium, and Vpremium Plank. Vamsi says the brand has installed over 710 million square feet of products so far and saved five lakh trees from being felled for making plywood.

After the successful launch of Vnext, Visaka remained clued into the next emerging market trend: renewable energy products. Solar panels were being installed on the roofs of houses, but as they were taking up terrace space, many people started avoiding this option.

Vamsi saw an opportunity.

“After two years of R&D (research and development), we came up with the idea of infusing solar energy in the building materials,” he says.

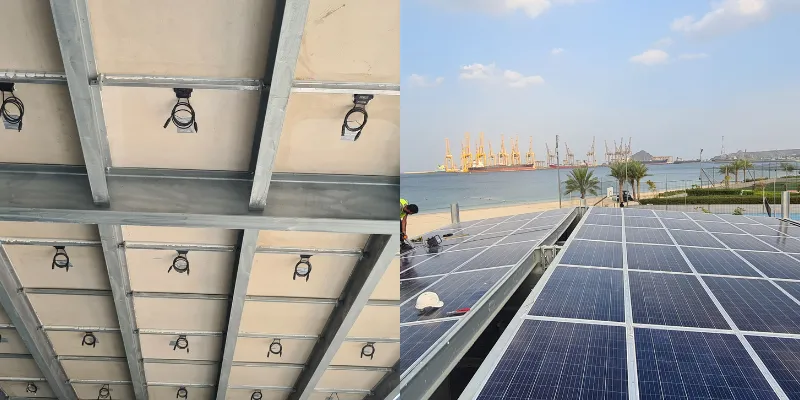

In 2018, Visaka launched ATUM, one of the world’s early integrated solar roofs. ATUM generates electricity and is a completely integrated, seamless solar roof made with poly or mono-crystalline solar cells and cement boards.

“It is a durable roofing material, making it the world’s first solar panel that can be directly used as a roof,” says Vamsi.

The same year Visaka launched V-Infill, a load-bearing wall solution made of steel engineered to improve construction speed and utility.

Visaka has also come up with Vnext solutions that cater to start-to-end construction and designing of space. It has helped in the sustainable construction of Amazon’s office in Hyderabad and Microsoft’s in Bengaluru.

Vamsi says Visaka’s primary aim is to make a difference to the world and society. That’s why the company moved away from making conventional manufacturing products to sustainable ones.

“Holding true to our pledge of sustainability and eco-friendliness, we have preserved 5,00,000 trees, prevented the emission of 90,000 tonnes of CO2, and recycled 100 million PET bottles,” he says. “We also manufactured vendor carts that are equipped with ATUM solar roofing and donated to the underprivileged.”

From India to the world

Visaka has 12 manufacturing units, 13 marketing offices, and a distribution channel with more than 7,000 dealer outlets spread across the country.

Vamsi says prominent clients for Wonder Yarn include British multinational retailer Marks & Spencer and Indian garments brands such as Raymond and Siyaram. Around 30 percent of Visaka’s textile products are exported to Europe and South America.

Visaka’s Vnext building products are exported to West Asia, the UK, and Australia, and are also supplied to government departments in the navy and MES.

Market dynamics

Today, Visaka is a conglomerate that employs more than 5,000 people. Although it has grown immensely over the years and expanded its product portfolio, capturing the market wasn’t easy.

Vamsi says that for any innovative thought, there is rejection. While in recent years, people have become environmentally conscious and started adopting sustainable solutions, the situation was quite different a decade ago, he recalls. The “sustainable pitch” wasn’t working for the company, so it changed tack.

“I remember when we started ATUM and pitched it as in-built solar in building materials, not many people were interested, but when we said it would save them roof space, they were fascinated,” explains Vamsi.

ATUM roof

Visaka now has a considerable market share in all the categories in which its products are present.

The company holds a 20 percent share in India’s cement roofs market, which has a total potential of 38-40 lakh metric tonnes (MTS) per annum. Vamsi says that as 50 percent of tar roofs are expected to be converted into cement roofs, the company plans to ramp up its output in this category further.

Vnext has around 25 percent share in India’s fibre cement board market, with a total potential of around four lakh MTS per annum. The plywood market in India is worth around Rs 25,000 crore.

Vamsi expects ATUM’s installed capacity to touch 40GW by 2022. Since its launch, ATUM has averaged 8-10 MW a year.

“There is a huge scope for this variant of hybrid innovation in the construction industry, and we intend to seize every opportunity that will help us capture the market,” he adds.

(Edited by Lena Saha)