A peek inside the facility that manufactures Flipkart’s MarQ TVs

How an e-commerce giant and a legacy electronics manufacturer are leveraging each other's strengths to understand, and then deliver, what customers want.

Blue plastic covers encase my shoes as I stand in a dimly-lit corridor, slightly terrified by the noise, as my host opens a door labelled ‘ELT’ (more on this later). High-decibel Bollywood music blares from television sets as people look on.

A few moments earlier, we had passed a sprawling room that had rows and rows of people with one hand ‘tied’ to their desks with a wire, synchronously assembling components on a conveyor belt. I try, somewhat unsuccessfully, to tell my racing heart that I am not in the ‘House of Horrors’, but, in fact, the manufacturing facility of Dixon Technologies.

Flipkart recently entered into a strategic partnership with consumer electronics manufacturer Dixon Technologies (India) to design and manufacture television sets for the former’s electronics and white goods brand MarQ.

Here is a brief overview of the manufacturing facility, located about two hours from the city of Dehradun, and how Flipkart and Dixon went from idea conceptualisation to execution in a span of a few months.

How MarQ was conceptualised

As a group of us journalists assembles in a boardroom along with representatives from Flipkart and Dixon Technologies, Adarsh K Menon, VP and Head of Private Labels at Flipkart, sits next to Sunil Vachani, Executive Chairman of Dixon Technologies, explaining the conceptualisation of the MarQ brand.

Flipkart and Dixon Technologies started from scratch in June 2017, and took an interesting approach to zero in on the features for the MarQ range of TVs. The companies picked out the seven best TVs in the market based on their research. They then picked out the best features in each of the televisions, and tried to incorporate those into MarQ televisions.

Adarsh, who has been with Flipkart for close to three years now, and has headed the categories of electronics and auto, noted that the companies were able to hit the sweet spot in most areas, and have either average, or above average features in the final range of TVs.

Flipkart has so far sold approximately 5,000 televisions, with a bulk of the orders coming during Diwali. Adarsh says the feedback has been overwhelming positive, but there are areas of improvement.

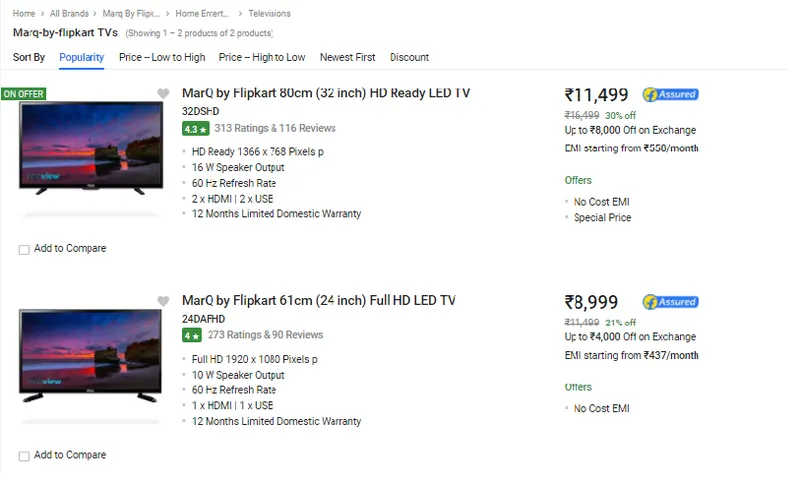

The MarQ range at present has televisions in two dimensions - 32 inches and 24 inches - priced at Rs 11,499 and Rs 8,999, respectively. At the time of writing this piece, the televisions had consumer ratings of 4.3 and 4.0, respectively. While it may be a little premature to call the MarQ brand a success yet, the brand seems to be on the right path.

Talking about the areas of improvement, Adarsh and Sunil - who has over two decades of experience in the electronics manufacturing services (EMS) industry - noted better sound range and clarity were the most sought features at this stage.

An overview of the manufacturing facility

Dixon officials say the company is the largest home-grown design-focused and solutions company engaged in manufacturing products in the consumer durables, lighting, and mobile phones segments in India.

It is also an original design manufacturer (ODM) of LED TV, semi-automatic washing machines and lighting products in India. As an ODM, Dixon develops and designs products in-house at its research and development centre. Based on the company’s product expertise, it produces televisions for major global brands like Panasonic, Sanyo, Akai, and now Flipkart’s MarQ.

A tour of the manufacturing unit and a crash course on manufacturing televisions follows. As mentioned at the beginning of this piece, some of the basic printed circuit boards (PCBs) are assembled by hand by a pool of employees seated in front of a conveyor belt, and Pankaj Sharma, COO at Dixon Technologies, explains the cable wire attached to workers’ hands.

Human bodies are capable of carrying small charges of electricity. These can be harmful for the PCB components. So, all factory workers need to have one hand ‘earthed’ to ensure no unnecessary current flows through the components.

Basic science, my engineering mind says, the heart, however, still refuses to believe all is well.

Back to the factory tour, and Pankaj explains that while PCBs are an important component, the display screens make up for about 65 percent of the bill of materials, or total manufacturing cost.

The glass used in our TVs is the same one used by most of the top brands. There are only seven FABs (semiconductor fabrication plants) in the world who make such glass.

He explains that effectively, 70 percent of a television is made in-house by Dixon Technologies at the 230,000 sq ft Dehradun facility. To this, Sunil adds that the facility has the capacity to manufacture 1.2 million TVs per year and the company is in the process of setting up another facility at Tirupati. The plan is to gradually move television production to the Tirupati facility.

Quality control and testing

All products manufactured by Dixon Technologies are tested comprehensively on critical parameters. Some of the product quality tests include those involving picture quality and audio reliability, power consumption and also Extended Life Test (or ELT – remember the room with loud Bollywood music?).

ELT involves maximising a television set’s volume and monitoring how it performs over an extended period of time and at what point it finally fails. Some of the manufacturing assembly line tests also include panel functionality, and picture quality checks in different viewing mode.

Flipkart says it uses a five-step quality check procedure when working with suppliers and manufactures. These include:

1) Supplier management programme: Flipkart selects suppliers through a rigorous process, which allows it to ensure that suppliers are the best-in-class, and able to offer high-quality products.

2) Product Selection: Customer feedback, benchmarking, and market research are used to define specifications of products.

3) Product Qualification: Prior to production, each product is measured on several parameters such as safety, reliability, functionality and local and international compliance/certification requirements by laboratories.

4) Production Monitoring: Flipkart says its quality checks are at par with international standards, and are conducted at each stage of the production - from raw material to the finished product.

5) Quality Control at Warehouse: Several parameters are monitored on a day-to-day basis to ensure safe storage and timely delivery of the product to the customer.

Flipkart also says all units producing MarQ products have to comply with stringent multi-level quality checks from process audits, and product performance tests at the factory as well as tests by independent testing agencies.

The long-term vision

Flipkart’s long-term vision with MarQ, and their other private labels, is to make excellent products affordable to value customer segments, which is over 70 percent of large appliance buyers on Flipkart. Adarsh says every product under the brand is priced 10-20 percent lower than comparable products from established brands.

So, while Flipkart’s private labels are competing with other brands, Adarsh reiterates, based on internal metrics, that private label brands will not cannibalise other brands in a category. In fact, private labels will actually lift the overall quality of a product category. So, in the long term, he believes it is a win-win for customers and brands.

Leveraging on the experience and knowledge derived from manufacturing consumer durable products, Dixon has an R&D centre in Noida which can verify and develop conceptual designs based on customer feedback, and convert such designs into deliverable products.

Flipkart, on its part, is looking to improve its private label products, and hence a combination of leveraging customer feedback points from Flipkart and Dixon’s R&D helps both companies tweak products faster and bring them to market.

In the long run, Flipkart’s MarQ aims to expand to more product categories. MarQ microwave ovens are currently available on Flipkart, and washing machines and air conditioners are some products in the pipeline.

Website- Flipkart, Dixon Technologies

(Disclaimer- The author travelled to Dehradun on a trip hosted by Flipkart)

Related read- A walk through Amazon India’s largest fulfilment centre in Hyderabad