Tech meets manufacturing to create growth opportunities through deeper customer experience

With boundaries that define how industries interact with their customers shifting, technology has become the game-changer that is disrupting the manufacturing world.

As per a recent report by McKinsey, the manufacturing industry is set to double to $64 trillion by 2030. Manufacturing has always been the mainstay of any economy around the world. However, earlier, it was seen as a monolithic industry. In this worldview, the actual customer was usually not an integral part of the process but a fringe player at best.

However, the boundaries that defined how industries interacted with their customers are breaking down and evolving into new ones at an ever-increasing pace. The challengers are no longer traditional manufacturers. For instance, in the auto sector, competition today stems from technology companies such as Google, Tesla, and Apple, which were never on the competitive radar of car manufacturers earlier.

Technology has become a game-changer, one that has already started disrupting the manufacturing world. We will look at how these interact with each other to create essential growth opportunities through deeper customer experience that, in turn, is the secret sauce to survival.

The leveraging of 3D printing, AI Digital twins, and a shared economy where co-creation and co-innovation with customers and partners is becoming mainstream.

Automation and IoT

These are no longer just buzzwords, but very much ingrained in our lives today. As per Gartner, by 2020 there will be 21 billion connected devices. With such a massive volume of available information, the opportunities to leverage it are immense.

Connected cars are one of the most widely used scenarios of IoT usage, with telematics playing a major role through cutting-edge technologies and solutions. As input costs continue to drop and necessary infrastructure becomes more prevalent, the potential for customer experience disruption is monumental when we start to project where these technologies will logically move with ramifications on how firms sell and service their products.

Age of servitisation

In the old era of manufacturing, services were never considered the mainstay of the manufacturing industry. But now the demarcation is getting blurred with manufacturers getting into the services side of the business and providing a complete solution to their customers.

Rolls Royce TotalCare is a perfect embodiment of servitisation in the manufacturing industry. Instead of concentrating only on manufacturing aero engines and relying on partners for correcting the defects, they have re-engineered their entire strategy by constantly monitoring the performance of the engines while they are in the air along with repairing parts as and when needed. This is a fundamental shift from their earlier model. And one that requires a deeper customer-centricity than was required so far. Tire companies are embedding IoT sensors in their tires to provide tires-as-a-service on a miles-driven basis.

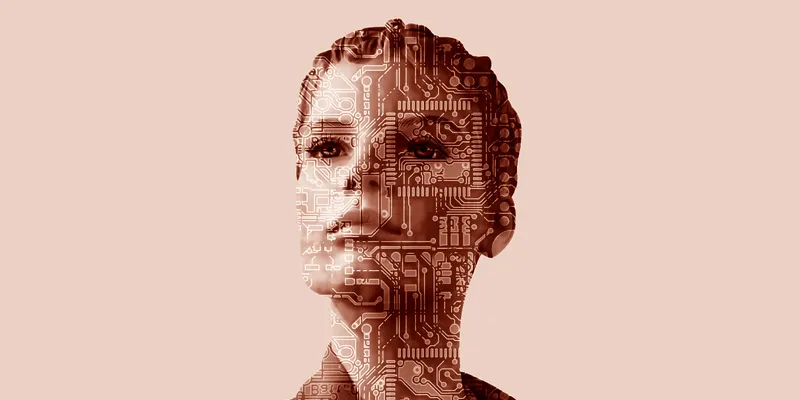

Artificial intelligence

Bots/manufacturing robots are not new to the manufacturing industry. The only thing that has changed is that they have become smarter and more reliable over the years. With new AI solutions such as virtual private assistants to workers or a self-learning production quality analyser, AI is already playing a big role in manufacturing. Self-learning robots will create a new workforce pool for manufacturers, with far-reaching ramifications on cost, agility, productivity, and scalability.

Trendforce predicts that the smart manufacturing market will reach US$250 billion in size by 2018.

Consolidation of sales and after-sales

It used to be the case that manufacturers had disjointed sales and service departments. This has changed; sales and after-sales are an integral part of a manufacturing organisation’s growth story. Both being revenue-earning streams, in many cases service is the more profitable one that cross-subsidises the original sale itself.

Customer centricity

Manufacturing has come a long way from just focusing on lesser downtime, and efficient production runs to a more customer-centric scenario where the customer is in the driver’s seat. Manufacturers are trying to lure customers to buy their products. Customer experience is a critical aspect and no one wants to miss the bandwagon, if they want to stay afloat in today’s competitive scenario.

Technology can enable a manufacturer to align various departments – marketing, sales, and service to work collaboratively to target the right customers and enhance the probability of converting them to being advocates.

A number of manufacturers have gone back to their drawing boards to revisit their strategy based on these trends. Those who haven’t done so and don’t plan to do so must be ready to face the consequences of this disruption.

Tectonic shift

The manufacturing industry is undergoing a tectonic shift from product-based to iterative solutions, connected experiences and service-based business models, which are shattering traditional economic models and creating new networked ecosystems. Hence from product design and creation, service delivery, customer interaction, relationship management, and the entire human capital engine with a high level of knowledge workers, needs have changed.

There is a need to be much closer to end customers, either in B2B, B2C or B2B2C to deliver the right products or services along with tailored customer experiences, while keeping an open innovation approach across the ecosystem.

“Digital leaders” have successfully created new capabilities by reconstructing the enterprise around digital operating principles with deep leverage of new technology like AI, real-time data analytics, IoT, mobility, cloud, microservices, and APIs, and have been successfully delivering better customer experience and business results than “digital laggards”.

(Disclaimer: The views and opinions expressed in this article are those of the author and do not necessarily reflect the views of YourStory.)