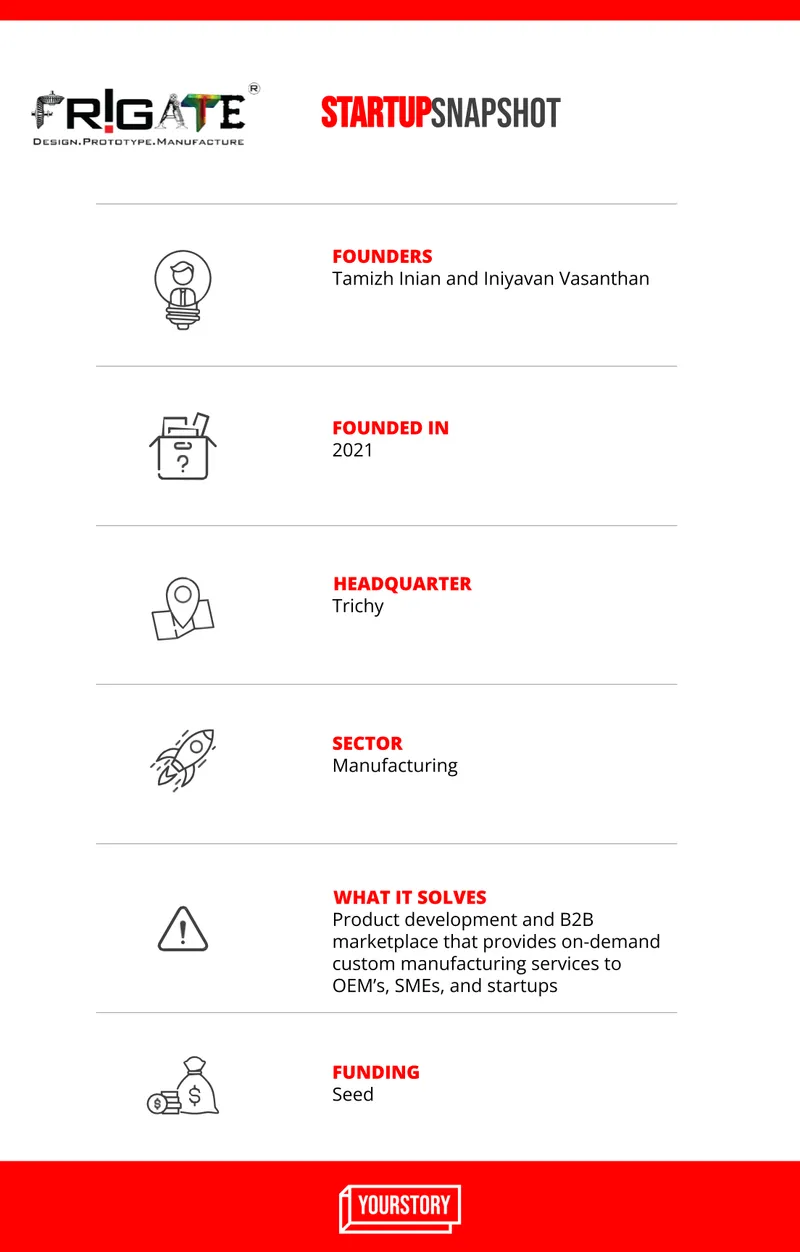

[Startup Bharat] Trichy-based Frigate provides on-demand custom manufacturing services to OEMs, SMEs

Founded in March 2021, Frigate is a cloud manufacturing company that provides fabrication, 3D printing, and CNC machining services to OEMs, SMEs, and startups.

In 2011, Tamizh Inian, who worked for an industrial solution provider as part of his company project, got an opportunity to work for a Tamil movie called Nanban, a remake of Bollywood movie ‘3 Idiots’. He and his team helped build a scooter prototype for the movie, which doubled up as flour mill.

What started as a project went on to become a successful business opportunity for Tamizh. He continued to build similar prototypes, earning close to Rs 9 to 10 lakh per annum.

Seeing the demand, he decided to turn this into a business opportunity and started in March 2021. Tamizh was joined by his brother Iniyavan Vasanthan as the co-founder in March 2022. Chandrasekar C joined as the CTO and Vivek Devaraj joined as the COO in 2022.

The Trichy (Tamil Nadu)-registered startup is a product development and B2B marketplace that provides on-demand custom manufacturing services to OEM’s, SMEs, and startups.

Since inception, Tamizh has built close to 1,300 prototypes. At present, Frigate has 27 clients, which consists of 20 manufacturing and seven prototype clients.

L-R - Vivek Devaraj, Chandrasekar, Iniyavan Vasanthan and Tamizh Inian

Early days

Most large companies want to focus on their core business and hence they outsource prototyping. This also has to do with the fact that sometimes they do not have in-house capabilities. And even if they have it, they do not want their resources to work on the same as outsourcing works out much cheaper for these companies.

Realising this gap, Tamizh decided to build a company in the product development space.

Initially, Frigate got projects from the automobile sector such as aftermarket parts of imported flights. Later, this grew into requests from various sectors such as healthcare and PSUs.

“India has a lot of gaps in the product development area. The personnel are technically skilled, but not good enough in marketing, which is not letting them go global. Their operations are getting delayed because they don’t have global experience,” says Tamizh, who has over 11 years of experience in product development and engineering design.

“We are leveraging this using our expertise,” he adds.

Focus on manufacturing

In the product development segment, large enterprises usually outsource work to different players. For instance, an automobile company outsources plastic products to one company and non-plastic to another, as different players have expertise in different sectors. But this takes away a lot of time for these enterprises as they would need to lookout for different players.

Frigate promises to solve this problem by being the single point of contact for any type of product to be manufactured or prototyped.

While solving this problem, the startup evolved itself from a prototype-only company to a full-scale cloud manufacturing company. It has an on-demand cloud manufacturing marketplace platform that provides fabrication, 3D printing, and CNC machining services. Frigate also sources the raw materials needed through this closed marketplace.

“Started as a prototyping company, we pivoted as our customers wanted their designs to be manufactured as well. For this, we onboarded SMEs from all over India to cater to the increasing demand from across the world,” says Tamizh.

Since last year, as the team started building more prototypes, it began receiving more orders for manufacturing. Using its marketplace platform, the company now connects with vendors who can provide them with the raw materials needed for manufacturing.

Until March 2021, Frigate claims to have completed close to 40 manufacturing orders from different segments, including orders from four EV companies, automobiles enterprises, defence, and aerospace.

It has a manufacturing unit in Trichy and Coimbatore, but the manufacturing at Coimbatore unit is being done in a different name.

The startup has onboarded 150 SMEs on the platform for making metal and plastic parts from Ahmedabad, Aurangabad, Jamshedpur, Indore, Belagavi, Thiruvananthapuram, Palakkad, Hosur, Trichy, Madurai, Erode, Salem, and Coimbatore to name a few.

Frigate also helps large enterprises to plan their activities effectively by giving them a lead time based on the machine availability and material sourcing, depending on the orders calculated on the platform as soon as the order is placed.

“This very feature of ours allows us to stand out from our competitors such as SMEs,” adds Tamizh.

At present, Frigate competes with Fictiv, xometry, protolabs, and sculpteo.

Camera car prototype done by Frigate for Vintage Camera's Museum, Singapore

The market and funding

According to IBEF, India has the potential to become a global manufacturing hub, and by 2030, it can add more than $500 billion annually to the global economy. India’s manufacturing sector has the potential to reach $1 trillion by 2025.

Frigate follows a business model where it charges a fixed margin for the product development/ manufacturing services it provides, which ranges from 10 percent to 300 percent.

The startup was started with an initial investment of Rs 10 lakh. In April this year, it raised a pre-seed funding of $175,000 from investors including angel investor Vel Kanniappan; Founders of , , , Wilco Source USA, and ; Abhishek Raj Pandey, Head of Sourcing and Procurement, ; Prabhu Sengodan of SPK Group; and other angel investors from the US, Japan, Germany, and Singapore.

The company said the new funding would be used to further strengthen Frigate’s technology stack.

Frigate is also developing an AI-enabled platform by identifying the topology of the design and sending it to the right machines available on the platform to manufacture the same by connecting machines via IIoT. It also plans to come out with the first set of technology stack within the next eight months.

“Tamizh is solving a real problem within the manufacturing space that I relate to,” said Srinath Ramakkrushnan, Co-founder of Zetwerk.

The team and plans ahead

The investment pitch was not the first time the founders and the investor met each other. They were introduced by a mutual friend during one of Srinath’s visits to Trichy, the city where both Tamizh and Srinath hail from.

Frigate currently has a 23-member team, with 13-15 working on prototyping, and eight on cloud manufacturing.

The startup is planning to increase the headcount to 100 members within the next fiscal as it is planning to set up offices in Chennai and Bengaluru. It also has plans to move its headquarters from Trichy to Chennai.

“We would like to acquire 200 more customers and be a $100M company in the next three years,” says Tamizh. He adds that the startup wants to increase the vendors from 300 to 600 by 2026.

Frigate is also in talks to be associated with auto majors Daimler, Ashok Leyland, and Mahindra.

Edited by Megha Reddy

![[Startup Bharat] Trichy-based Frigate provides on-demand custom manufacturing services to OEMs, SMEs](https://images.yourstory.com/cs/2/40d66ae0f37111eb854989d40ab39087/ImagesFrames72-1653573084446.png?mode=crop&crop=faces&ar=2%3A1&format=auto&w=1920&q=75)

![[Startup Bharat] This 4-year-old Tamil Nadu-based milk delivery company has onboarded thousands of farmers, consumers](https://images.yourstory.com/cs/2/40d66ae0f37111eb854989d40ab39087/ImagesFrames63-1653496621431.png?fm=png&auto=format&h=100&w=100&crop=entropy&fit=crop)