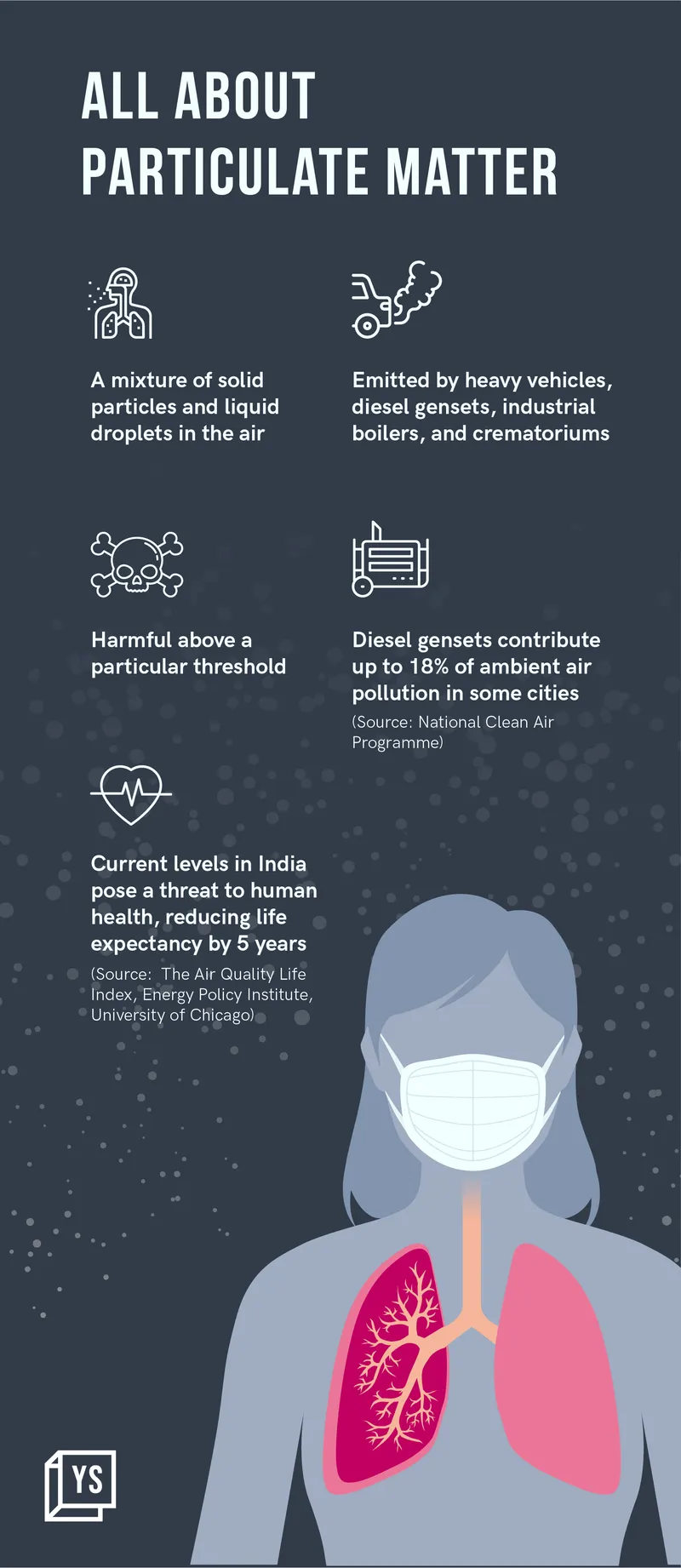

Towards cleaner air: Pi Green’s filterless retrofits aim to control emission at source

Pune-based startup Pi Green is creating technology-driven solutions for the reduction of particulate matter emitted by diesel gensets.

As toxic grey haze envelopes North Indian cities every year in November, the problem of air pollution becomes real and visible. Advisories are issued and policies come into effect.

To deal with the high levels of emission in the air, the Delhi government bans the use of diesel generator sets, considered a major contributor to pollution, from October 15 to March 15 in Delhi-NCR, under the Graded Response Action Plan.

Pune-based is trying to solve this issue with retrofits to control the hazardous exhaust emission released by diesel gensets.

“The problem we’re trying to solve is particulate matter emission at source and ambient air,” says Irfan Pathan, Co-founder and CEO, Pi Green Innovations.

According to the company, unlike existing solutions, which use filters or water-based solutions, Pi Green provides a filterless solution that reduces the need to change filters.

The technology, which is patented in more than 30 countries including the US, the UK, European Union, China and Singapore, is the brainchild of Rizwan Shaikh, the co-founder of the company.

Starting up

The story goes back to 2016 when Rizwan and Irfan met at an event in Pune.

Rizwan, who was running an AC servicing shop, had created a machine enclosed in a wooden box, which when fitted to a scooter converted the smoke from the vehicle into powder. Irfan, who was at the event to talk about his cold coffee venture, saw a video of Rizwan’s nascent product, which he had been pitching to investors.

Irfan was intrigued and thought it was a good idea to invest. An elevator pitch at the event was followed by a meeting at a McDonald’s outlet, 15 days later, to hash out the details. “We wrote the business plan on McDonald’s tissue paper,” recalls Irfan.

Rizwan and Irfan concluded that the product required an investment of Rs 15 lakh to Rs 17 lakh, and Irfan put his own money into the venture.

But it wasn’t smooth sailing, as the duo failed many times before they came up with an efficient product. They developed 40-45 prototypes of varying efficiency levels before they achieved a particulate matter reduction of over 90% during a vehicle test conducted in late 2018.

Shantanu Sonaikar, who ran a corporate finance consulting business then, advised Irfan during the initial days—on the business and its growth prospects—as Pi Green engaged in pilots, prototyping, and validation and set up a team. Later, Shantanu joined as a co-founder in 2018.

Says Shantanu, “With Irfan and Rizwan, over two to three years, I was invested in the entire concept of Pi Green and what it brought to the table.”

By this time, Irfan had already put in close to Rs 1.5 crore into the business. But Pi Green was still in need of capital to function and to apply for patents. So, armed with definite proof of concept, the three partners decided to raise money from investors.

In 2019, the three of them incorporated the partnership firm into a company. Then, in the same year, Pi Green raised a seed funding of $300,000 from Harshal Morde, Director of Morde Foods. In 2021, the startup raised over $4.5 million in a Series A round led by the investment fund Opus Consulting.

How the product works

Traditional solutions are operations-heavy and expensive, according to Irfan. Pi Green, he says, has tried to address these issues in its device through design interventions.

Pi Green’s ‘carbon cutter’ technology is based on the principle of an electrostatic precipitator. This is commonly used in thermal power plants by companies such as Forbes Marshall and Thermax.

The electrostatic precipitator uses high voltage to charge particles in a gas stream. The charged particles, smoke, in this case, are attracted to electric plates, resulting in soot, and relatively clean air comes out (70-80% clean).

Retrofit device from Pi Green Innovations to reduce particulate matter emission from diesel generators

“The major issue with an electrostatic precipitator is there’s a lot of downtime to clean the plates and operating costs too,” says Irfan.

To address this, Pi Green patented a self-cleaning mechanism through design modifications.

The electrostatic precipitator unit is typically very bulky. For an industrial boiler, it could be as big as a three-storey building. Pi Green has succeeded in reducing the size of the precipitator for smaller applications in diesel gensets.

The company’s retrofit device is about a quarter of the size of the diesel generator (usually 40 feet long, 8 feet wide, and 14 feet high). As it is filterless, the problem of changing filters every few months or a few years does not arise.

Typically, the filter accounts for 40% of the device cost. With a filterless device, this cost is saved.

The carbon cutter machine has been custom-designed for specific loads of diesel gensets. It uses the battery of the diesel genset to draw power for the electrostatic process, using less than one unit of electricity in 10 hours.

“Our product is about 20% to 30% cheaper than that of the competition. It is not only the cost of the product, it includes the full cost of ownership as well,” says Shantanu.

Pi Green’s solution has won awards and recognitions from Smogathon in Poland in 2018, World Wildlife Federation in 2019, and Clean Air Challenge by UNDP in 2021.

Growth story

The company signed its first customer in 2020. It received its second order, also its largest order, worth Rs 1.32 crore, on December 31, 2021. Since its launch, Pi Green has made over 150 installations.

Today, Pi Green has 70-80 customers, including large OEMs, hospitals, ports, and clients from the manufacturing industry, in India and abroad.

Pi Green says its revenue was Rs 2 crore in FY2021 when it operated for only four months during the pandemic. In FY2022, the revenue rose to Rs 12 crore. In the current year, the company aims to reach Rs 100 crore.

Currently, the startup serves Tamil Nadu, Gujarat, Andhra Pradesh, Maharashtra, and Delhi-NCR. Maharashtra. It competes with companies such as Chakr Innovation and Novorbis Itus.

The diesel generator market in India is estimated to grow at a CAGR of 9.4% to $1.8 billion by 2030, according to a report by P&S Intelligence Market Research.

Challenges

Speaking about the challenges the company has had to face, Irfan says, “Everybody rejected us two-three years ago, saying it (the product) is not possible and it’s not going to work.”

Now, these companies are Pi Green’s customers or are in talks to be its customers. Earlier, the challenge was about survival and whether the product would work or not. Today, it is about engaging with governments.

“Having a sustainable business model is also equally important,” says Shantanu.

Other opportunities

The startup is testing a prototype for heavy vehicles; it measures 3 ft x 1.5 ft and can be fitted under vehicles. It is also working on an after-treatment solution for industrial boilers and is in discussions with a couple of municipal corporations for pilots on crematoriums.

The company is also exploring opportunities in international markets, including Poland in Europe, Southeast Asia, and other parts of Asia.

Edited by Swetha Kannan