These two young girls used the lockdown to innovate critical solutions for climate change

Based in Mumbai, Antara Patel (11) and Prisha Patel (12), designed a sustainable solution to cool down the heat emitted by large AC units' condensers, and their device won the 2020 World Robot Olympiad.

Antara Patel and Prisha Patel felt gushes of uncomfortable warm air blowing from the AC units’ condenser behind a supermarket while walking in Mumbai. They realised the irony that the condenser (the outdoor portion of air conditioners) was heating up the environment to ensure a comfortable shopping experience inside the supermarket.

“Besides heating up the micro-climate, it was also very uncomfortable for the pedestrians passing by,” says Antara.

The young girls learnt that appliances like AC have an adverse impact on the environment, almost immediately. In fact, when compared to other home appliances like refrigerators, ACs consumed higher amount of energy as well.

Six months since that first realisation struck, the duo designed an affordable and sustainable cooling solution using simple materials like hay and clay cones. The preteen duo formed Team Technonerds, and participated in the 2020 World Robot Olympiad (WRO), winning first prize in the global robotics competition for young people.

The annual championship was held virtually, organised by WRO Canada this year, and saw over 26,000 teams from 75 countries developing robotics-based solutions on the theme, Climate Squad. Participants were judged virtually based on videos, live interviews, and presentations.

Antara and Prisha’s prototype for the contest is now safely placed on the terrace of Prisha’s house in Mumbai and is functioning as intended. The girls built their product under the tutelage of coaches at On My Own Technology (OMOTEC), an online coaching platform for Robotics courses.

A sustainable cooling solution

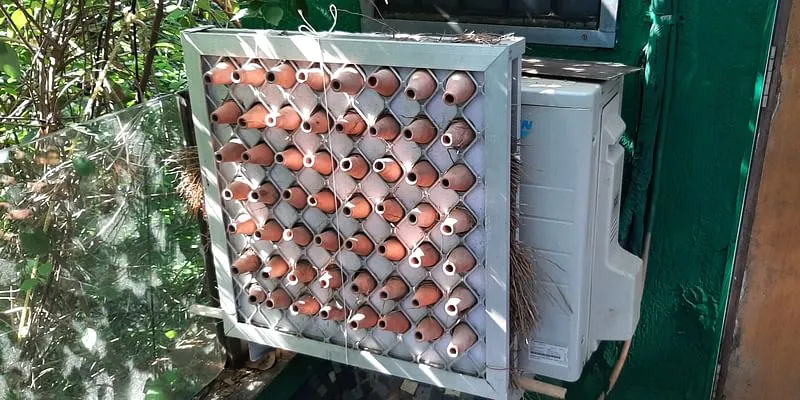

Prototype by Team Technonerds

Students of Jamnabai Narsee School in Mumbai, Prisha (12) and Antara (11) were first introduced to the world of robotics and technology about four years ago.

The device they built has been named Aqua Clay Atmosphere Cooler or ACsquare. An aluminium grid frame affixed with earthen clay cones, the device needs to be wetted to cool the hot air released by the condenser. The gaps in the frame are filled with hay to ensure that hot air does not escape.

Antara and Prisha tried different materials like concrete and plastic, and finally settled on clay sourced from Dharavi for the best result. Prisha adds that the device has close ties to Indian heritage, as similar designs were seen dating back to the Harappan civilisation.

The shape and size of the cones were based on scientific concepts like Boyle’s Law and the Venturi Effect. “We went for small cones because if the cone breaks – which is not likely – there will be many others to continue the cooling work. And they are easier to place on the grid,” Antara explains.

Additionally, waste water from AC, RO water purifier, and washing machines can be reused to keep the cones moistened, and cool down the hot air from the condenser. The duo applied pipe irrigation method by carving holes for water to pass through.

The cooling process begins within seven minutes of switching on the AC. To keep track of the performance of AC and filter, temperature and humidity sensors are connected with a robotic circuit.

To easily monitor the efficiency, they designed an app using MIT App Inventor to show real time data and allow users to set the preferred temperature for optimum cooling and energy efficiency.

Navigating the market and other lessons

Antara and Prisha say their innovation is a tested and fool proof device, and they are looking to launch in the market as well. The size of the device can be increased to suit bigger AC units.

The girls have revised the design by incorporating feedback from architects and engineers and presented at the Indian Institute of Architecture as well. Moving ahead, they plan on launching commercially through architects and engineers, so their device can be used while building houses. They believe it would help them scale at a higher rate.

Having spent around Rs 1000 on developing the prototype, they plan on quoting Rs 1200 in the market.

The duo says six months of lockdown time spent on devising the solution has been an exciting learning journey. “From understanding electronics and app making to using new age technology to modify traditional methods - it was all a wonderful experience.”

Keen on solving real life problems, they hope to participate in more robotics competitions in the future.

Edited by Anju Narayanan

![[Funding alert] Bengaluru startup Invento Robotics raises undisclosed fund from MSPL Limited, others](https://images.yourstory.com/cs/2/e641e900925711e9926177f451727da9/Imageoc4z-1596548194654.jpg?fm=png&auto=format&h=100&w=100&crop=entropy&fit=crop)