Artificial Intelligence spearheading a Technological Revolution in Manufacturing

“The future is already here – it’s just that it isn’t evenly distributed – William Gibson.”

We are living in an interesting time where the boundaries between fiction and reality are blurred. Robots and intelligent machines are assisting humans in all walks of life. By 2030, Artificial Intelligence will add a whopping $15.7 trillion to the global economy.

For decades, manufacturing was considered the leading industry with the highest levels of automation. Now, manufacturing is all set to race ahead of other industries, thanks to huge investments in emerging technologies. Artificial Intelligence, Machine Learning, and Robotics 2.0 – the holy trinity of futuristic technologies – are positioned to lead us into the next manufacturing era especially in this COVID-19 times, this is more relevant than ever before.

The Future is Here

Today, factories are making use of AI-enabled systems to optimize their functioning and increase profits. Here are a few examples of how AI is revolutionizing manufacturing. The corporate technology unit of Siemens in Germany has designed a two-armed robot that can assist workers in manufacturing without special programming. Landing.AI developed by Google can accurately identify product defects within fraction of second.

Changying Precision Technology, a manufacturer in China, has managed to reduce its manual workforce from 650 workers to around 60, by deploying an army of robotic arms. Introducing these smart machines has helped the firm achieve a whopping 250% increase in productivity while bringing down manufacturing defects by 80%.

In Japan, robots outnumber human workers in the FANUC factory. The country is investing in 30 million AI-enabled robots to win back its position as the world's number one manufacturer.

In this article, let’s see the impact of AI and machine learning on the manufacturing industry. We will also take a look at how robots and AI will transform processes and industry landscape.

Current Status of Automation in Manufacturing

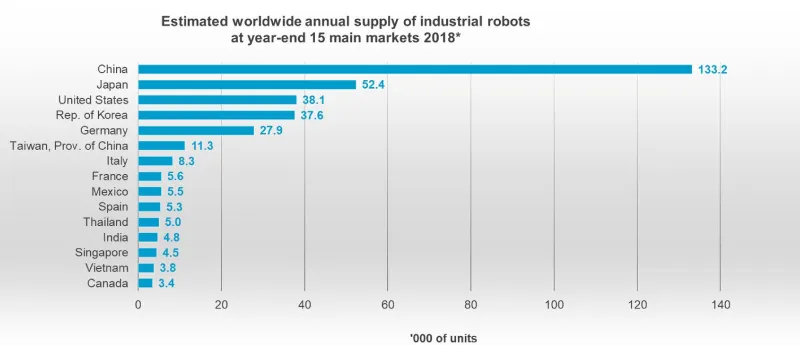

Reports released by the IFR (International Federation of Robotics) reveal that nearly 384,000 units of robotic arms were shipped in 2018 alone. China is the leading market for AI (35%) in manufacturing followed by Japan and the US. India ranks 12 and accounts for 4.8% of robotic arms sold in 2018.

Source: IFR

Among all industries, automobiles and electronics manufacturing lead the world when it comes to implementing AI, robotics, and machine learning.

Machine Intelligence will drive the Future of Manufacturing.

Manufacturing today has undergone massive transformations in style, process, techniques, and efficiency. Machine intelligence has helped streamline operations, reduce downtime and resource consumption, and enhance production efficiency while increasing customer satisfaction and the bottom line.

Before we analyse deeper, let's first understand what is Machine Intelligence.

What is Machine Intelligence? Machine intelligence is the summation of artificial intelligence and machine learning. Simply put, it’s the branch of technology that uses AI to make machines smarter.

Top Ways in which Machine Intelligence is revolutionizing the Field of Manufacturing

Industry 4.0

The rise of AI and smart machines have ushered in the era of the fourth industrial revolution. The cornerstone of Industry 4.0 is the development of intelligent factories – a highly sophisticated autonomous system capable of functioning with little to zero human interference.

Another critical component of Industry 4.0 is the digital twin. It's a visual model of a physical process that offers real-time data about the physical entity or process. Digital twins help manufacturers experiment dynamically, thereby enhancing the outputs without the fear of disrupting the performance or damaging existing equipment.

AI-enabled Generative Design

AI systems can help in optimizing

designs. The human workforce – product designers, provide the input parameters. These parameters are fed into the system – cost limitations, material requirements, etc. The AI-system then generates a wide array of design alternatives. With the help of machine learning, these systems can produce the optimal design. This process can be applied in several industries like aerospace, automotive, consumer products, etc.

Predictive Maintenance

One of the biggest challenges facing manufacturers is – unplanned downtime. AI can help in reducing downtime with the help of predictive maintenance technology. Predictive maintenance helps in identifying a defect before it occurs, thereby drastically reducing downtime.

According to the ISA (International Society of Automation), downtimes lead to loss of manufacturing capacity up to 20%. With predictive maintenance, unexpected equipment failure can be prevented. It eliminates the guesswork and reports the machines' conditions in real-time, which is a challenge even for experienced system engineers. Thus, operations continue as planned without any disruptions, saving both time and money.

When the AI-system notices a malfunctioning piece of equipment, it automatically alerts the maintenance engineer. AI-driven predictive maintenance helps in increasing asset productivity by up to 50% and cuts maintenance costs significantly. Defect detection rates are increased by 90% when compared to manual inspection.

Supply Chain Management

AI plays a crucial role in optimizing supply chain management. It helps in predicting demand at each stage of the process, with the help of historical and real-time data. Today, supply chains are highly complex and contain thousands of diverse components. Even a single delay, error or breakdown can shut down the entire system.

With AI, manufacturers can better predict the complex interactions between different components of the supply chain. It helps in numerous tasks like:

- Spotting irregularities in resource use

- Determining the ideal inventory levels

- Streamlining resource requirements to reduce downtime

- Increasing production speed and reducing costs

- Improving the bottom line

Robots in Manufacturing

When we think of the future of factories, we imagine a sophisticated assembly line handled by robotic workers. For years, robotic arms have been used in assembly lines for repetitive and precise tasks. Besides robotic arms, cobots (collaborative robots) have been used in factories. Cobots are lightweight and small, work along with humans and are advanced to adapt to environmental changes.

With the advances in robotic technology and machine learning, we are close to achieving "lights-out" factories. This wholly automated plant works with ZERO human interference.

Product Optimization

Product optimization is the process of controlling production parameters to achieve maximum efficiencies and maximum outputs. Machine learning algorithms can analyze vast quantities of data collected from sensors and predict the best metrics to boost production.

ML algorithms help in achieving optimum production by controlling variables and provide the right recommendations to factory operators.

AI and Machine Learning creating the Factories of the Future, Today

AI and machine learning is no longer a figment of science fiction. It’s happening right now and will continue to flourish in this new decade. It’s transforming manufacturing both today and tomorrow. From robots as co-workers to taking over hazardous jobs, AI, machine learning, and robotics are revolutionizing manufacturing like never before. By optimizing production, we can reshape the economy, making us self-reliant while also catapulting us to become a global leader in manufacturing. In this COVID-19 times, this is more relevant than ever before.

Author is a raising new voice in Digital World today. He authored one of the bestselling book of 2019 - Digital Construction Management. He is known for his passion for technology and successful implementation of many digital programs of government of India such as FASTag- electronic toll collection system on national highways, Portals for e-Tender & e-MB, automation of highway sector, development of Project Management Software and many citizen centric mobile apps. His recent contribution is development of Artificial Intelligence based Data Lake at NHAI. An IIT & ISB alumni, strategist and excellent administrator, Akhilesh is one of the respected technocrat of India.