This Chennai startup is recycling about 250 kg of plastic waste per day entering the sea

Chennai startup Samudhyoga Waste Chakra uses advanced technology to derive value out of plastic and liquid waste in a decentralised, digitised, and decarbonised fashion.

Single-use plastics, plastic packaging, and multi-layer packaging have become a growing concern over the years. While technology has advanced, it is yet to create a sustainable impact.

According to a report by Central Pollution Control Board (CPCB), India generates over 3.3 million metric tons of plastic waste each year.

While many plastic recycling units are not eco-friendly and produce harmful emissions, this Chennai startup is here to change that.

Established in 2019, Samudhyoga Waste Chakra uses advanced technology, which derives value out of solid and liquid waste in a decentralised, digitised, and decarbonised fashion.

The startup is working to make the best out of solid and liquid waste produced in domestic areas. It is working on a pilot project with the South Chennai Corporation to launch a pyrolysis plant that can prevent 250 kg of plastics from reaching the oceans per day to produce 200 litres of oil with zero emissions for industrial use.

DZEEP - The team members with a DZEEP unit.

The journey

Samudhyoga started as a five-member team in 2018, which was participating in a ‘Carbon Zero Challenge’ organised by the US Embassy in collaboration with IIT Madras.

At the time, the team began looking into the plastic waste management scenario and realised that only 9 percent of plastic waste is recycled globally.

They also understood that 60 percent of the plastic waste generated is packaging waste, including multi-layered packaging (MLPs), which cannot be treated by the mechanical recycling infrastructure present in India.

When the team visited recycling plants, they saw a very centralised operation. In fact, plants that were doing chemical recycling were closed, owing to their emission issues, sourcing problems, operation inefficient, and far from sustainability.

“We saw potential there. While there's no lack of technology at the plants, the emission standards were poor. We wanted to develop something safe, efficient, and scalable and established Samudhyoga,” Keshav Vijay, Business Head, Samudhyoga, tells SocialStory.

The team won Rs 5 lakh from the competition and got access to IIT Madras’ incubation cell. In fact, they also started looking for funds to pursue the project.

In 2019, they got a seed fund of Rs 1 crore from Engineers India Limited, which helped them kickstart their project, and came to be known as Samudhyoga Waste Chakra.

“The startup aims to establish a decentralised plastic waste treatment system to handle the non-recyclable plastic waste,” says K Sivagami, Co-founder, Samudhyoga Waste Chakra.

“By properly converting the plastic waste into oil, the startup will save ocean and Earth from millions of microplastics. To envisage that the product can help to mitigate the climate change at a large scale gave us the confidence to establish the Samudhyoga,” she adds.

The founding team of Samudhyoga Waste Chakra

Waste recycling technologies

Samudhyoga has worked on two technologies — DZEEP and EcoFert.

Decentralised Zero Emission Energy-efficient Pyrolysis or DZEEP is a unit that converts 1,000 kg of plastic (mixed plastic, MLPs, and polyolefin) to 800 litres of oil with zero emissions and high performance through the process of pyrolysis. This unit requires about 2,500 square feet of land.

The pilot project will be completed in south Chennai by July, where a system will be implemented that can recycle 250 kg of plastic waste per day to produce about 200 litres of oil. The project costs about Rs 1 crore, but it will be much lower when implemented on a larger scale, the startup says.

“The oil generated can be used as furnace oil for the production of steam in boilers, and generators with an appropriate proportion of diesel. We are also exploring a purpose to use oil as petroleum feedstock for the production of raw materials,” Keshav shares.

The startup’s second technology, EcoFert, works on processing urine released to water bodies that cause eutrophication (increasing mineral content in water bodies).

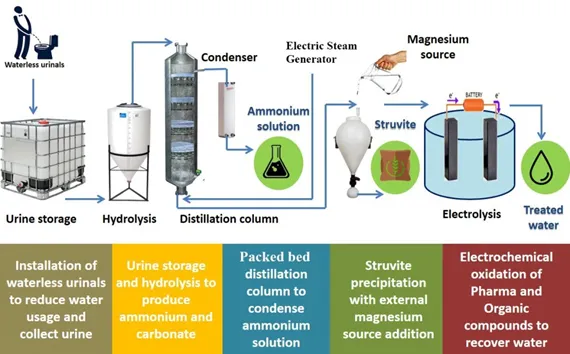

“We came up with a technology called EcoFert that can process urine and recycle water to make toilets a sustainable sanitation technology. From 1,000 litres of urine, the unit recovers 850 litres of water, 100 litres of ammonia, and one kg of struvite. The recovered water is sent back to the system for flushing and gardening purposes. The ammonia is sold, and the money earned is used to develop community toilets,” Keshav explains.

EcoFert can only be used in urinals and presently is implemented at the Engineering Design Department of IIT Madras with a 500-litre system. This unit produces about 50 litres of ammonia every day and can save water consumption of 10,000 people per day.

Schematic diagram of the EcoFert system

Zero-emission systems

The startup has environmental engineers, including Indumathi M. Nambi, the startup’s director, also a professor of the environmental department at IIT Madras. These engineers ensure the gas emitted from the whole process is passed through an advanced gas recovery system, where a column of scrubbers removes the harmful gases and are combusted, thereby reducing emissions.

“So, once the gas is combusted, they are converted into simpler compounds, which ensures there is no emission of dioxins and furans, a major concern with other projects,” says Keshav.

Speaking about other eco-friendly aspects of the technologies, he says, “We invest a lot in automation. About 30 to 40 percent of our manufacturing cost goes into automation, ensuring optimal functioning of the entire system of energy generation.”

The gases recovered are used in a secondary heating system to save energy, reducing the power consumption from electrical grids.

EcoFert occupies one-fourth of a room. However, the team is planning to make it more compact for easy instalment anywhere.

Challenges

“When we entered the industry, our biggest challenge was to change the narrative of this industry. People had to be more confident about the potential of chemical recycling, and what it holds for India if done in an eco-friendly manner. We are trying to prove that this could be a profitable, sustainable, and safe system. We are trying to change the narrative of the industry itself,” shares Keshav.

In the last six months, Samudhyoga has been part of the AIM Smart City Accelerator programme. The accelerator programme — born out of Ashoka University in Sonipat, Haryana, in 2016 — was launched to empower startups working on three issues — healthcare, sanitation, and waste management.

“We’re looking to venture into smart cities as we have developed certain standards and connections. We are planning to at least have a couple of systems on each of these cities, which can address the packaging waste and MLPs, and generate more utility from plastic wastes,” says Keshav.

Besides, the startup is also targeting a decentralised model for units across India, which generates over one ton of waste per day within its infrastructural facility.

Edited by Suman Singh