This 19-year-old from Mumbai is making PPE suits ‘cooler’ and more comfortable

Nihaal Singh Adarsh, a 19-year-old student from KJ Somaiya College of Engineering, Mumbai has developed compact ventilation system called ‘Cov-Tech’ for PPE suits.

When the fast-spreading coronavirus pandemic reached different countries, frontline healthcare workers took up the challenge head-on, putting their own lives at risk to save others. While the general population has been using face masks as the first line of defence, health workers have to wear PPE suits as they are more prone to catching the infection.

While these kits are extremely protective when it comes to safeguarding from the virus, wearing them for long hours results in profuse sweating, which can further lead to fungal infections.

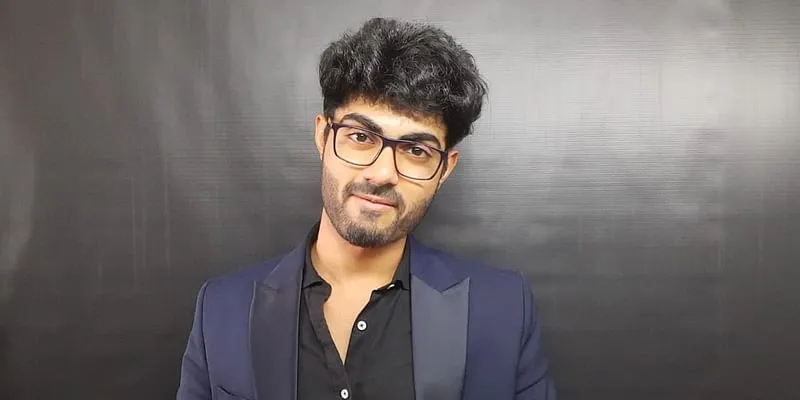

Nihaal Singh Adarsh

To combat this problem, Nihaal Singh Adarsh, a 19-year-old student from KJ Somaiya College of Engineering, Mumbai has developed a compact ventilation system called ‘Cov-Tech’ for PPE suits, through his startup Watt Technovations Private Limited.

“The purpose behind creating the 'Cov-Tech Ventilation System' is to bring comfort to the healthcare professionals working to fight the COVID-19 pandemic in a safe manner,” Nihaal tells SocialStory.

The product caters to doctors and medical practitioners who are currently working in high-risk environments.

Aiding the fight against the virus

The ‘Cov-Tech’ system has a compact, ergonomic design specifically designed to work as an add-on to existing PPE kits, thus removing the need to change the design of PPE suits.

“I had to ensure that the design was not only compact but also affordable, considering that the existing technologies that work on similar lines are expensive,” Nihaal says.

The system can suck in the air from the environment, filter it through a polypropylene fibre filter – which has a tested filtration efficiency of more than 99 percent, and push inside the suit.

The Cov-Tech Ventilation system

The positive pressure developed inside the PPE suit escapes through the region around the wrists and near the neck, ensuring that a continuous airflow is maintained within the suit. This keeps the user cool and also reduces the problems that were caused by sweating such as tiredness, itching, and infections among others.

While the innovation might be the need of the hour in the medical industry as of now, it is also useful elsewhere such as in the chemical, pharma, and mining industries.

Funding and support

Registered last September, Watt Technovations received the NIDHI Prayas grant of Rs 10,00,000 from the Department of Science and Technology, Government of India for prototype development and product innovation with the help of RIIDL (Research Innovation Incubation Design Laboratory), a not-for-profit organisation under Somaiya Trust. The startup also received a support of Rs 5,00,000 from the New Venture Investment Programme (a joint programme conducted by RIIDL and K J Somaiya Institute of Management) for marketing and other expenses.

With this support and by using RIIDL’s laboratory, Nihaal was able to devise a product priced at Rs 5,499.

Gaurang Shetty, Chief Innovation Catalyst, RIIDL says, “We encourage students to innovate. We provide a foster environment to help the innovator to make the best output. A team of teachers and supervisors support the startup and help them at every stage.”

The ventilation system attached to a PPE kit

Nihaal also received support from Dassault Systèmes 3D Experience Lab India, which provided him with lab facilities while he was at Pune.

“When it came to filters, I had to find out which one works best. I was fortunate to be able to work with a senior scientist, Dr Ulhas K. Kharul, at the National Chemical Laboratory (NCL) where I could learn more about the filters,” says Nihaal.

While he has received calls from other industries, including chemicals manufacturers, Nihaal is currently focusing on the medical fraternity to help them during these trying times.

While all this support helped him develop the product, he says, "None of this would have been possible without my parents and my friends, since they have been supporting me constantly in my efforts."

Challenges and the way forward

“The biggest challenge was just about facing each day, irrespective of whether the previous day was a failure, and pushing myself to work on it again and again,” Nihaal shares.

But acquiring resources posed a problem due to the lockdown. At times, he had to travel from Pune to Mumbai just to buy a few motors and batteries.

Moreover, the challenge when it came to the design was that the device needed to be non-invasive, and also be able to maintain a decent airflow. In fact, he developed over 11 prototypes, of which about six were only about developing something more compact. Only the 12th prototype was commercialised.

As for the road ahead, Nihaal wants to modify the concept PPE kits across the globe from being uncomfortable. In addition, he also wants to develop other products like wireless stethoscopes, a concept that doesn’t need physical contact with the patient.

“We have a couple of ideas that we work on, but first, I want to finish my engineering, finish my higher education from an Ivy League school, and then give back to my country,” says Nihaal.

Edited by Kanishk Singh