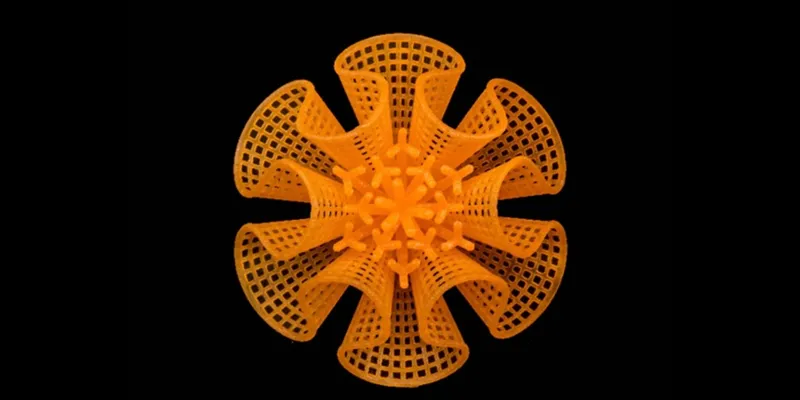

3D Printing the impossible

Making the impossible designs of yesterday possible today

My undergraduate was in PES IT college in the field of Mechanical Engineering. During this time we were building Formula race cars for the University to participate internationally. We came across 3D printing technology to build some of ur bespoke components during the time. In the process we realised this technology has some significant value as it helped us save time on our projects.

Ever since then ( 2008 ) i have been intrigued by the possibilities of 3D printing and the use cases.

My family has been in the jewellery business for over 30 years and my sister Esha Bagla is a Gemologist by education. For this reason i was always intrigued by the possibilities of application of 3D technology for jewellery application.

Hence i decided to pursue my masters in UK and I have a research degree from Loughborough University in the field of additive manufacturing ( 3D printing)

Specialisation of 3D Printing for designing parts using advanced metal technology to leverage the design freedom offered by 3D printing tech.

Unique understanding of the way the industry works and the gap between the technology and the end user whose in varied fields

Having started the company in Bangalore in 2013 we faced a lot of difficulty owing to the lack of precision manufacturing eco system which drove me to relocate to Taiwan in 2015. Ever since i relocated theres been a huge upswing in the business we do and we’ve been able to accomplish fantastic milestones over the last 12 months and create a high performance 3D printer suitable for jewellery , dental , hearing and engineering based applications.

Our Business is highly complex as it involves knowledge of mechanical, electronic, software, materials, optical and chemical engineering. Possessing and integrating this knowledge base to build what we make its incredibly complex and satisfying at the same time.

The future of 3D printing lies in Knowing this sweetspot where theres a valid business case and having the technological solutions to the challenges which would help 3d printing transition from a $6 billion industry to a $100 billion is where my knowledge and experience would come in.

I can write this very differently but these are some thoughts

Essentially my University in Uk wrote something like this

http://www.lboro.ac.uk/alumni/our-alumni/ayush-bagla/

http://www.3dprintingbusiness.directory/news/ackuretta-launches-ackuray-a135-professional-dlp-3d-printer-8-resin-materials/