Starting from a small garage, how an Indore-based entrepreneur built a Rs 400Cr turnover agarbatti brand

Mysore Deep Perfumery House was started in Indore in 1992 by Prakash Agrawal, who began by making agarbattis in his garage. Today, its flagship Zed Black processes over three crore incense sticks, selling 15 lakh packs every day.

Even seven years after Prakash Agrawal quit his sales assistant job at a textiles store in Indore, he couldn't find success as an entrepreneur. His attempts at manufacturing and selling soaps, detergents, and hair oils all proved to be unsuccessful.

Prakash’s mother didn’t want him to continue manufacturing and failing. The family had limited means, and she always wanted her son to pursue a stable job in the textile shop. But he was adamant and wanted to stick to entrepreneurship.

One fine day in 1992, Prakash’s mother told him that as he couldn’t succeed as a manufacturer, he should become a distributor for any established agarbatti (incense sticks) brand.

He took this as a challenge instead – wanting to prove his mother wrong by becoming a successful manufacturer. But even Prakash had to admit that agarbattis were a good idea. The Indian market for agarbattis was flourishing in the 90s on the back of a swelling demand.

Speaking to SMBStory, his son Ankit Agrawal said:

“My father did not have any capital. In 1992, he borrowed Rs 5 lakh from some relatives to start an agarbatti manufacturing business Mysore Deep Perfumery House (MDPH) and agarbatti brand Purab Paschim Uttar Dakshin. His younger brothers Shyam and Raj Kumar joined him in the effort.”

And so, Prakash and his brothers began making agarbattis out of a small garage in their Indore house. His mother joined to supervise the labour and production processes.

Ankit Agrawal (left), Partner, MDPH, and Anshul Agarwal (right), Partner, MDPH

The early years

In those days, Bengaluru and Mysuru in Karnataka were the primary hubs of agarbatti manufacturing in India. When Prakash tried selling his Purab Paschim Uttar Dakshin agarbattis made in Indore, customers were not convinced of their quality. High-quality agarbattis were perceived to be exclusively from Karnataka, especially Bengaluru.

“Any manufacturer not from Bengaluru did not get any space or respect in the Indore market. My father found it difficult to sell his agarbattis and recover the cost of production,” says Ankit, who is now a director in the company.

Despite this, Prakash forged ahead relentless. He began focussing on catering to local tastes and preferences through Purab Paschim Uttar Dakshin. It took him six years of persistent brand building to gain market share and make enough money to move production out of his house and into a factory.

The brand started doing well but Prakash wanted more – to experiment with a new brand with an English name and colourful packaging.

This led him to launch ‘Zed Black’ under parent MDPH in 2000. With this, Prakash wanted to make agarbattis with a wide range of pleasant aromas and long-lasting fragrances. But at the same time, he knew he had to ensure consistency and offer the products at value-for-money prices.

The experiment proved hugely successful and Zed Black was almost like a revolution in the industry. Soon, it became one of the fastest-growing agarbatti brands in India, and Prakash began selling lakhs of agarbatti packs across the country on a daily basis.

But, just as MDPH began to flourish, the company faced a major setback. In 2003, there was an accident at its factory, which caused a huge fire. Agarbattis are flammable and the flames spread out of control, gutting the entire factory.

“It was a major financial setback for the company. After the fire, MDPH had to once again start manufacturing from scratch. This time, we rented a facility and began making agarbattis,” Ankit says.

Zed Black 3-in-1 agarbatti

Model of success

The good news was that Prakash had already found a business model that worked well before the disaster. He was able to regain the lost momentum and soon got back on track.

Once sales picked back up in 2003, MDPH moved into a bigger manufacturing setup in Indore. Six years later, it set up another manufacturing unit in the city.

Then, the company diversified into making dhoopbattis, dhoop cones, vaporisers and essential oils, edible oils, mosquito coils, mehendi powder, soya chunks, rice papad, and more.

But the focus was always on agarbattis. Its flagship brand Zed Black became one of the top three agarbatti brands in India, selling via 7.5 lakh retailers, 3,500 distributors, and exporting to around 30 countries, claims Ankit

He adds that MDPH managed to build a network of 36 company-operated depots across India.

“Today, the company has four manufacturing units in Indore with a cumulative floor space of 6.5 lakh square feet. The third unit we set up, in 2018, is the world’s largest raw agarbatti manufacturing unit and has more than 550 machines. More than 2,000 workers are involved in the manufacturing process across our units, out of which 75 percent are women,” Ankit says.

At present, the company processes over three crore incense sticks and sells 15 lakh retail packs of Zed Black agarbattis in India every day. In 2019-2020, it is targeting a turnover of Rs 400 crore.

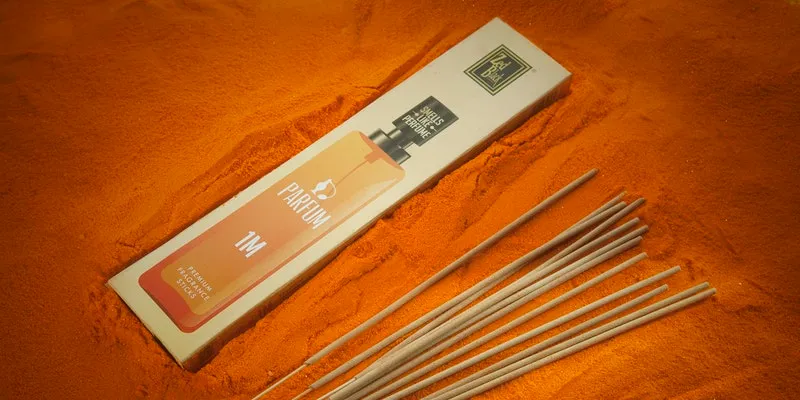

Zed Black's Parfum agarbatti

In the agarbatti segment, MDPH plans to become the largest player in India and exports to over 60 countries.

“The Zed Black brand faces competition from different brands across regions. Brands which are strong in a particular area or state provide competition to Zed Black in that region,” Ankit says.

According to him, the brand will continue to focus on selling to married women between the ages of 30 and 50 as agarbattis are primarily used for pujas. It is targeting them through social media marketing activities on Facebook, Twitter, Instagram, and YouTube, and its presence on ecommerce platforms Amazon and Flipkart.

The company’s above-the-line marketing activities include TV and newspaper ads, while its below-the-line strategies are point-of-purchase marketing, product sampling initiatives, distributor conferences, retailer schemes, etc.

Eventually, MDPH wants to venture into making products like camphor and chandan tika, and build its consumer brands in the food and confectionary space.

(Edited by Saheli Sen Gupta)