Now you can 3D print an entire house at low-cost in 24-hours

“Any sufficiently advanced technology is indistinguishable from magic”: Arthur C Clarke.

3D printing is wowing the world. You can practically print anything you want. Printing toys, chocolates and guns is now child’s play. With researchers printing human livers, ears and unborn babies (using images from an ultrasound), it seems the only limitation is our imagination.

Well, what about printing an entire house in 24-hours? Yes, possible.

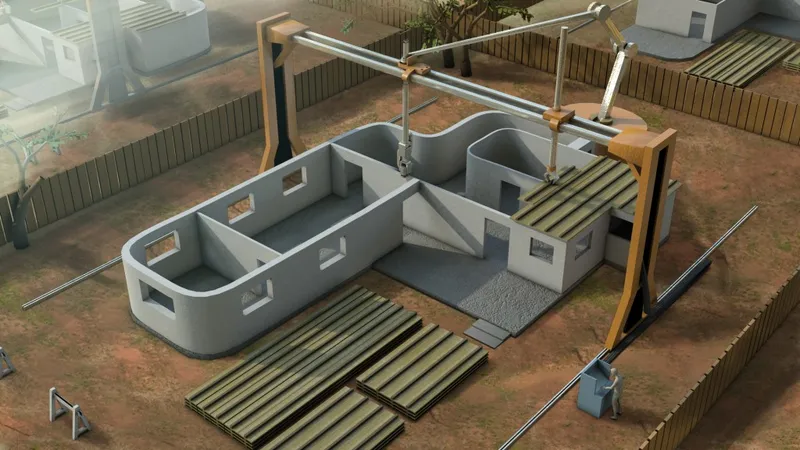

Thanks to Behrokh Khoshnevis, a professor of Industrial & Systems Engineering and director of Manufacturing Engineering Graduate Program at the University of Southern California (USC), who has created a technology called contour crafting (CC) that lets you do this. A single house or a even colony can be custom-designed and constructed in one run, and what’s more it comes complete with wiring for electrical, plumbing and air-conditioning.

The technology has not been commercialized yet, and remains a college project, but it is being field tested by many organizations including NASA (CC technology can be used for building space colonies). The development of CC is being supported by the National Science Foundation and the Office of Naval Research.

With its inherent promise of making housing affordable and fast to build, this kind of technology, when commercialized, holds great promise for a country like India . Not to mention the immense environmental benefits due to the use fewer materials for construction and reduced wastage.

Possibilities for the India affordable housing scenario:

India’s housing shortage at the end of tenth plan was 24.71 million dwelling units for 67.4 million households, 98 percent of this was in the low-income and economically weaker sections (EWS) segment. The shortage is expected to worsen to 26.53 million houses for 75.01 million households. The three biggest challenges in servicing this market is high cost of land and construction material, and lack of financing. Considering that construction costs for affordable housing contributes to nearly 60 per cent of overall cost, reducing costs could have a considerable impact on the future of affordable housing.

According to The International Finance Corporation (IFC) the estimated investments to meet this housing requirement through 2012 is close to $80 billion. Since the government is responsible for providing housing to the poor, it will bear the brunt of this expenditure, therefore any type of savings through technologies like CC will be welcome.

Since these structures are very strong (10,000 PSI), it could also solve the problem of safety concerns, which India faces with affordable housing. The poor, seeking cheap housing end up living in unsafe buildings, which have led to many of them collapsing in the past.

Contour crafting: How does it work?

CC uses automated versions of age-old hand wielded tools like the trowel, computer created designs, robotic arms for the construction, and extrusion nozzles that help fill the concrete. First the outer layers are fabricated using quick-dry concrete and using a trowel the layers are smoothened and brought into shape. Then using nozzles, robots and a computer-controlled gantry system (type of crane) the inner layers are filled. Essentially CC piles layers of concrete one on top of each other rapidly to build a house in no time, with almost zero wastage of construction material.

Watch this video to understand how it works.

The man behind the invention:

Khoshnevis is a well-known researcher and inventor. He has been working on CC technology since the 1990s and regularly conducts lectures and seminars on invention and technology development. In 2006, it was selected as one of top 25 best inventions from more than 4000 inventions by the National Inventors Hall of Fame and the History Channel’s Modern Marvels program.