Roots of labour: IIM alumni's startup Barton Breeze brings farms to your doorstep

Gurugram-based Barton Breeze sets up fully-automated hydroponic farms using its in-built technologies to grow clean and pesticide-free vegetables.

We all know that home-cooked food is the best. But what we really don’t seem to consider is the backend process – vegetables grown using chemicals, pesticides, and insecticides to increase their yield. These chemicals get accumulated in the soil, and in turn, increases the plant's uptake of chemicals. As a result, by the time the food reaches our plate, it would have lost half its nutritional value, and we might be consuming vegetables with high pesticide residues.

Solving this pain-point is Gurugram-based Barton Breeze. Started by Shivendra Singh (31) in 2016 in Dubai, UAE, with a mission to bring technology innovation in the farming sector, Barton Breeze focuses on Hydroponics. It is a method of growing plants without soil by making use of mineral nutrient solutions. It reduces water consumption as well as increases yield.

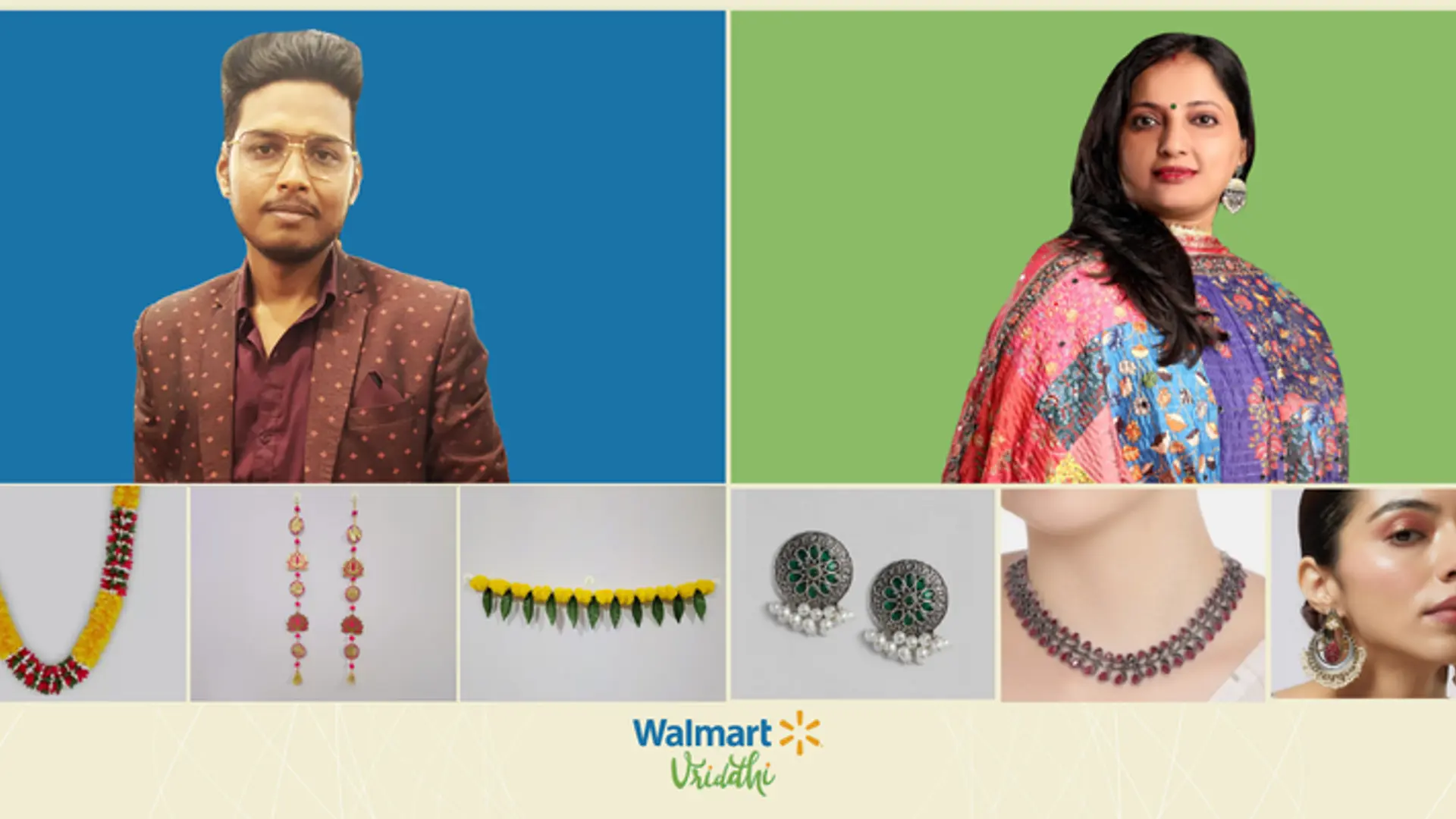

Shivendra Singh, Founder

Also read: Stanford Seed startup Future Farms is out to solve India’s food crisis with clean, soil-less farming

The company, which started operating in India by the end of 2017, wants to give ‘clean food’ to its customers throughout the year, without being affected by the changing seasons.

At present, Barton Breeze grows 28 varieties of crops, including edible flowers, eight different coloured bell peppers, lettuce, different varieties of tomatoes, and micro-greens at its farms across India.

The beginnings

After graduating from IIM Ahmedabad, Shivendra worked with the Landmark Group in Dubai. Later, in 2016, he started working on a pilot project around hydroponics and set up two container farms in Dubai. Shivendra says, it was then he met Ratnakar Rai (49), an Agro Technologist, in an agri-tech meet.

“We shared our thoughts on the need for hydroponic and clean food in India, and soon he joined me on my second research project,” says Shivendra.

After setting up a branch in India, Ratnakar, who specialises in Controlled Environment Agriculture, joined the company as the Co-founder.

Shivendra and Ratnakar Rai (L-R)

“Ratnakar can do magic in agri-support and operation. But we needed tech support for faster growth, and that’s when Dheeraj joined us,” Shivendra adds.

Dheeraj Joshi (35) has over 14-years of experience working with software and automation companies in India, the UK and Singapore.

While keeping Dubai farms operational, Barton Breeze entered the Indian market by the end of 2017. The company has developed six fully-automated farms within a year in four states namely Haryana, Rajasthan, Uttar Pradesh, and Uttarakhand.

However, “Getting skilled operators was impossible, and we had to train and build our own ground staff team. We are now a team of six core members, supported by 14 field farms,” says Shivendra.

Quality control using tech

Barton Breeze builds farms, operates it, and directly sells the produce to the customer. This end-to-end operation not only reduces the final cost to the consumers, but also ensures total control over quality.

The team claims to have built fully-automated farms using its in-built technology.

“We have built a software where we clip a device on the leaves and stem of each plant. The software is connected to the computers, and informs the user when a particular plant needs more nutrients or minerals,” says Shivendra.

However, the journey wasn’t as easy for the team. “The supplier base was limited, and so we developed products ourselves and encouraged vendors to develop a few,” says Shivendra.

As a result, Barton Breeze has five hydroponic products developed in-house. This includes Nutrient Film Technique channels, home gardening essentials, and consumables like plat nutrition, net pots, and grow media.

The startup is now a retail supplier of these products, and this “adds up to 15 percent of our revenue,” Shivendra adds.

Inside a Barton Breeze farm

Also read: Here's how IIT and ISB alumnus is bringing ICUs and cancer care to patients' homes

Revenue model

Barton Breeze designs and fabricates automated farms for its clients, which are then operated and marketed by the team on a yearly service agreement.

Shivendra says,

“The annual service agreement comes with a minimum annual return on investment of 30 percent. However, if a client wants to operate or market by themselves, they are open to do that."

Currently, out of the eight farms set up by Barton Breeze in India, two are operated by the company itself. For this, it has deployed in-house trained staff. Each of these farms follows a daily checklist standard operating procedure, and the agronomist team keeps an eye on the regular activities.

“We charge nine to 14 percent service fee on total sales revenue, depending on the size of the farm and other parameters,” Shivendra says. The average size of these farms is 1,000 sq mt.

The marketing team analyses the market demand and then decides on the choice of crop. “The marketing team provides a seedling schedule to the farm supervisor in advance. The farm itself takes care of all the operational expenses after the first harvest,” says Shivendra.

Some of Barton Breeze’s key clientele include Hero Steel, True Leaf, Milkbasket, Naffaq, and JVL.

The startup has also developed a low-cost ‘Home Growing Kit’ to enable consumers to grow their food with minimal time and investment.

At present, Barton Breeze operates eight farms in India, two farms in Dubai, and does consultation in Qatar.

Shivendra with Jumbo Lettuce

Number game

According to Shivendra, it costs around Rs 2,500 per sq mt to develop a fully-automated hydroponic farm, and an additional Rs 1,400 per sq mt for the polyhouse construction. “The amount gradually reduces with the increase in farm size,” he adds. It takes up to two months to build an automated farm, including a polyhouse.

The company has generated Rs 1.8 crore in revenue since 2017, with a CAGR of 300 percent in 2018.

“Based on our expansion plans, we are targeting a revenue of Rs 10 crore in financial year 2019, at a CAGR of 800 percent,” Shivendra says.

Initially bootstrapped, each farm now takes care of its operational expenses by selling the produce.

Market overview and future plans

According to Stratistics MRC, the global hydroponics market will reach $724.87 million by 2023, growing at the rate of 18.1 percent between 2016 to 2023. At present, startups like Goa-based BitMantis Innovation, Himachal Pradesh-based Junga FreshnGreen, and Chennai-based Future Farms are working in the hydroponics farming sector.

However, Barton Breeze is “not just a hydroponic farm developer, but also a farmer and a retailer,” says Shivendra.

Its end-to-end solution enables it to control the quality of the product and services,and enables reduction in the final cost by 30 percent, when compared to the ones available in the market.

Keeping the consumer needs in mind, Barton Breeze now wants to build automated terrace farms on residential towers and commercial buildings. “This will allow consumers to directly have access to clean and fresh food, free from pesticide and harmful chemicals,” Shivendra says.