How to minimize the impact of COVID-19 on your supply chains and Q1 earnings

How to minimize the impact of COVID-19 on your supply chains and Q1 earnings

As we draw closer to the first quarter of 2020, it is upsetting to find out the global impact of the COVID-19 on the world economy.

There are forecasts on how there would be a global recession this year, with growth falling to 0.9 percent by economists from Goldman Sachs and Morgan Stanley. So it is important that companies and business owners resort to best practices to reduce or eliminate the impact of the disrupted supply chain on their manufacturing and distribution.

Over 400 companies report the impact of the Coronavirus on their Q1 earnings.

The outbreak of this epidemic is affecting the global economy more than we know and can imagine. The disruption in demand patterns, trade restrictions, geographical limitations, and the fear of the citizens is succinct. The major portion of this impact can be attributed to the complexity of the supply chain models that polarized the revenue crisis.

What’s wrong with the supply chain models?

The complexity of the supply chain in addition to lack of awareness on what is happening around and how it affects every organization calls for reformative measures in the way we consume news and the happenings around the globe.

First, let’s understand the supply chain models and then analyze the gaps.

The structure of the supply chain includes - the channels of distribution, frequency of the supply, modes of transportation, warehouse models that determine the storage, and more significantly the sources from which these originate.

Turns out, the supply chains originate majorly from the quarantined regions of the Corona epidemic.

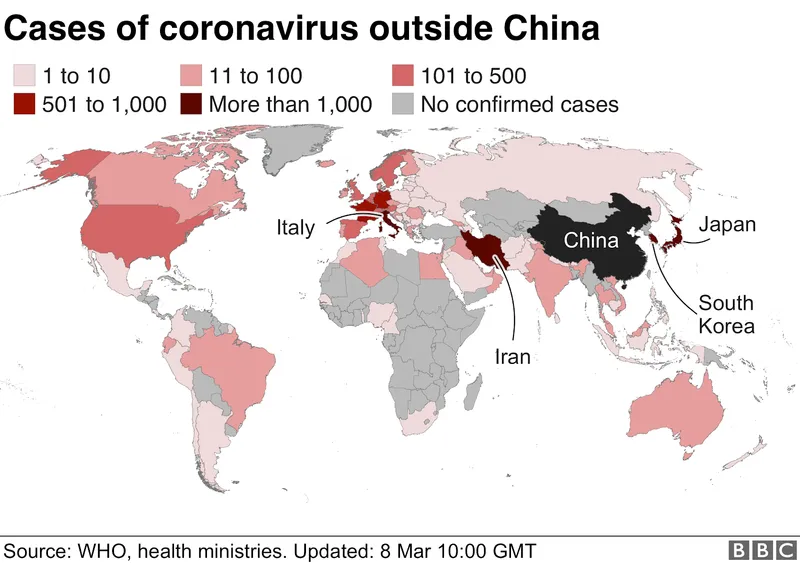

Let’s have a look at this map.

Clearly, China, South Korea, Italy, and Japan have been heavily affected. There are solid predictions on other regions that are likely to suffer in the coming days. With this data at our disposal, let’s have a look at the dependence of the world’s largest 1000 companies on these quarantined areas to source their supplies.

These companies do understand how crisis management works in case of a mishap, but what do they not know?

Their network of suppliers - the heat map of the locations of their middle and lower tiers. More often than not, these companies do not directly deal with the lower tier suppliers most of whom are based out of the quarantine zones. Without enough knowledge on what their supply chain looks like, how do they intend to manage such a huge crisis?

Consuming information isn’t easy anymore!

With organizations adapting to remote working and the supply chain networks getting completely disrupted, the best way to prevent and stay cautious of any mishaps is by staying abreast of what’s happening.

A clear picture of the regions that are affected and the ones that are likely to be impacted will give business owners a brief time for preparedness. Following the news, magazines, and phone apps will give a scattered picture of what’s happening around and it becomes difficult to filter out the ones that are relevant to you and pick those that would plausibly impact your business.

From Apple Inc to apple fruit sellers, every business is affected..

The CEO of Apple said, “The Apple supply chain is relatively more important in China”, and that he’ll be watching the coronavirus situation unfold in Korea and Italy since Apple has suppliers and businesses there as well.

China is not just the most populous nation, but also responsible for more than 16% of the global GDP.

For the automotive sector, a supply shortage of key components and auto parts due to the Coronavirus outbreak has caused some major auto manufacturers to temporarily halt operations in South Korea (Hyundai Motors, Ssangyong Motors, and Kia Motors) and Japan (Nissan) as they seek supplies from China and other markets.

The global pharmaceutical supply chains have taken a hit too. Wuhan itself is host to major domestic Active Pharmaceutical Ingredient (API) makers, post the pandemic, China is considering holding onto material supplies of certain antibiotics and exporting less to other markets including the U.S.

With China’s supplies plummeting down, companies that have extensively mapped their supply chains would be able to better forecast and prevent the crisis. While others, who do not have a rough idea of their contractors, subcontractors, lower-tiers, origins of supplies, and the locations through which these supplies pass through will suffer losses.

How to stay informed of the events that affect your business?

As a part of your supply chain risk management efforts, you must take up risk monitoring. Begin by setting alerts on specific keywords and brand names that would significantly impact your business and make room for sufficient precautionary measures.

There are market intelligence and news monitoring solutions that are available in the market that will help you monitor news and other significant happenings that are relevant to your business. You can stay notified on crucial pieces of information like the spread of COVID-19, regions affected, safety measures imposed by other businesses, and more.

The challenge with supply chain disruption is being able to manage and track:

- Forecasting: Find macro signals/trends related to different regions. For eg. raise in diagnosed cases, govt policies regarding the closure of transport, lockdowns, trends about the time it takes to spread to nearby geographies, etc.

- Real-time information & Communication: Tracking social media & websites of the supply chain provider businesses to get a sense of any sentiment changes to have the right questions to ask the supplier

- Logistics: Mapping shipping routes and options based on disruptions in flights, travel restrictions to determine alternate options and plan-B's. Increase in costs of shipping (for eg. air cargo rates skyrocketed because flights were canceled due to low passenger rate)

- It is not just supply chains but because of the global disruption and the expected recession, even the customer market segments and the product mix are likely to get affected. This would need quick changes to the business model and strategic decisions around future supply chain decisions. It is important to be able to get the right data at the right times to be a step ahead.

Well-informed, Misinformed, or Ill-informed? The choice is yours…

Take the first step by collating relevant information from around the globe at your fingertips by filtering out what you need and eliminating irrelevant and bogus information. We hope the situation will subside soon and urging you all to stay safe. While we can try our best to oil the continuity of our business, we must also not forget to take care of our safety.