How this farmer’s son went on to build an award-winning machine tools business from Aurangabad

Started from a rented old shed with one worker, Tool Tech Toolings has marquee auto companies as clients and employs 400 people.

Just as the hard and rocky terrain of Aurangabad in the Marathwada region of Maharashtra hides the soft, delicate sculptures and fresco paintings of Ellora and Ajanta caves, similarly, amidst the hum of machinery in its industrial zone throb inspiring stories of grit and determination.

In the Waluj industrial area of Aurangabad sits a 6,000 sq metres manufacturing facility proudly displaying its name, Tool Tech Toolings, and greeting visitors with its lush greenery. Its shop floors are as spic and span as its manicured gardens in the front.

This is how Founder and Managing Director Sunil Kirdak had always visualised a world-class factory when he was in the process of building one.

Sunil with his awards and trophies. (Photo by author)

When he visited large fancy factories to collaborate with them, their attention to the whole vibe of the place would fascinate him no end. “I would think apna bhi ek din aisa hi world-class factory hona chahiye (I should also have a world-class factory like this one day),” he says while giving a tour of his facility.

Established in 2004 from a second-hand shed that no one wanted to rent because of a fire accident earlier, today Tool Tech Toolings is a well-known name in machine tools employing 400 people and recorded revenue of Rs 82 crore in the pandemic year.

It is an ISO 9001:2015 certified company equipped with Industry 4.0 for manufacturing of CNC and VMC (technologies used for motion control of machines), forge components, electrical assembly for automobiles, manufacture of fixtures, gauges, special purpose machines, and robotic automation.

Most of his clients are top brands in the automobile industry, including Bajaj Auto, Honda, Yamaha, TVS, Volkswagen, Skoda, Royal Enfield, and Siemens.

Accidental entrepreneur

It took 44-year-old Sunil many years to see his dream factory take shape. But as is with people who make the most of what they have been dealt with in life, Sunil too did not start out with dreams of building a machine tool factory. His humble middle-class background had drilled hard the value of education and a stable job. “Only if we do well in education, we can do well in life. That was my father’s philosophy,” says Sunil.

He studied BE mechanical engineering and MBA in finance from Aurangabad and subsequently took up a job as a trainee in a company in the same town. But he confesses that he was not happy with his 9 to 5 job. There was something missing.

Dreaming big is not the foundation on which middle-class aspirations are built in India.

Nonetheless, after a few years, he thought of starting something of his own. In 2002, along with his four friends, he started a machine tool business but within two years the partnership broke and they had to call it quits.

“At that point in time, my wife was pregnant. I came home that evening and was sitting in the dark, upset at the turn of events,” he recalls. His wife suggested he start again on his own. “She said one simple thing. ‘I am going home to my mother’s house for the delivery and will not come back for another three/four months. You have that time to give your full attention to your new venture’.”

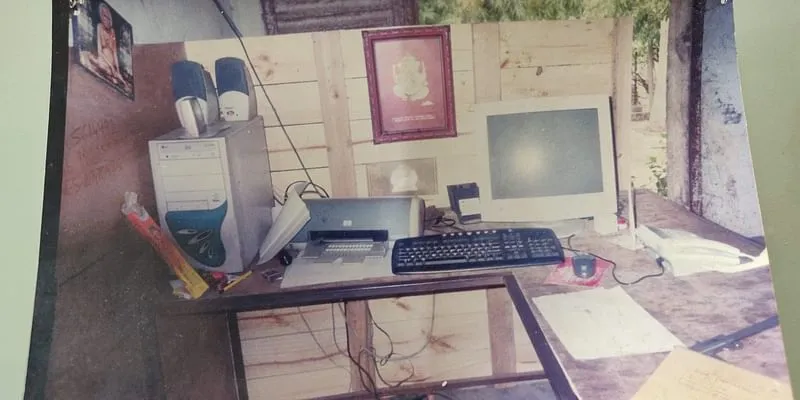

A picture from Sunil Kirdak's early days when he started out of a shed hangs on his office wall.

Armed with his wife’s confidence in him, he bought one lathe machine and one drilling machine out of his contribution from the partnership. “I hired an autorickshaw and took the machines to a shed I rented out at Rs 6800 per month in Chikalthana industrial area of Aurangabad.”

Sunil set up the two machines and hired one worker. “I had a good reputation in the market. In a few days, I got an order of Rs 50,000 from a company. In our business at that time, people would give 50 percent advance. I got components from scrap and used the advance to fulfil the order. I was the worker, engineer, designer, and accountant,” he says with a smile.

After the first two orders, offers dried up. A friend of Sunil’s was setting up a children’s hospital and needed someone to make the beds, saline stands, and other furniture. “That’s how I got into fabrication to survive. For six months, I made small fixtures and such just to keep the business running.” Slowly, he hired more people, bought more machines for fixtures, gauges, hydraulic, and special purpose machines. He says,

“In the beginning, I would see only a few bicycles standing outside my shed. Slowly, these were replaced with motorbikes as I hired more people, and that gave me a sense of achievement.”

Towards industry 4.0

He eventually acquired land and decided to expand his business into electric component manufacturing. “A big client came to us and said we will help you with cash flow,” says Sunil sharing how he got a breakthrough in his business. Instead of the 45-day cycle for payment, the client reduced it to 15 days for a period of three years. “That helped us tremendously,” he says.

They were approached by Siemens and thus started another facility for them and added an electrical plant. In 2015, they diversified into forging with clients like Kalyani and Yamaha.

Tool Tech Toolings' shop floor.

“We started this business from Aurangabad, and I used to get orders as low as Rs 200. Today, only five percent of our orders are from Maharashtra, the rest of the 95 percent is from all over India,” Sunil adds. His company also exported machines to the US and China. They have built a new assembly line for chassis, frame, silencer, exhaust system, and so on for auto clients, including Baja Auto, Honda, Yamaha, TVS, Volkswagen, Skoda, and Royal Enfield.

The machine tool industry is a highly competitive one with some top guns occupying the head of the table, including Bharat Fritz Werner Ltd, ITL Industries Ltd, and Jyoti CNC Automation Ltd among others. The machine tool market in India is predicted to grow by $1.9 billion during 2020-2024 at a CAGR of nearly 13 percent during this period.

Despite the positive outlook, COVID-19 has tested the industry too.

Sunil, who is the winner of two national awards — National Award for Research and Development and First-generation Entrepreneurship Award, says the pandemic has forced him to innovate in trying times. The revenues from his automation division saw a decline, though he expects this year will be better. He availed of a top-up loan recently to maintain his supply chain.

He says the lockdowns have given him an opportunity to diversify, and he started a new product and a new vertical, domestic kitchen sink, which he says is doing well. He has also acquired land in the Delhi-Mumbai Industrial Corridor Project to set up an R&D centre, which will be completed by Diwali this year.

Tool Tech Toolings' factory interior.

Make in India success story

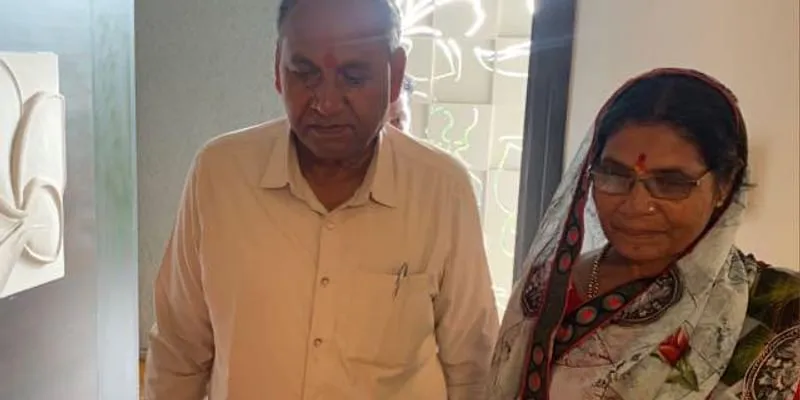

Son of farmers from Adas village in Beed district in Maharashtra, Sunil says he draws inspiration from both his parents. His mother took up the family’s farming occupation in the initial years when his father expressed his desire to study.

The family moved to Aurangabad when Sunil was six. His father eventually retired as director of higher education after having completed his own education and rising through the ranks from being a professor to head of the department.

Sunil Kirdak's mother in her farm.

In 2012, his parents returned to their village where they practice progressive farming involving innovative drip irrigation and have become profit-making farmers in the village. “When he started there were no ponds in the village, today there are 50 water ponds because of rainwater harvesting,” Sunil says. His parents are assisting other farmers to adopt new farming techniques.

Sunil Kirdak's parents.

“From them, I have learned that earning money is a byproduct. For me, developing the product is about passion,” says Sunil. But he rues the fact that in India entrepreneurs are not nurtured. “The reason why MSMEs do not grow to be a brand is that they only think about money from day one. The government policies are also to be blamed because only if you have land, will you get a subsidy. They give subsidies not to the entrepreneur but to the land.”

But for a company like Sunil’s to be based in a Tier-II town with its own set of challenges and yet have big clients like TVS come all the way from Chennai to Aurangabad is in itself a ‘Make in India’ success story.

Edited by Saheli Sen Gupta